Blasting, UHP & Site Equipment

Showing 121–135 of 646 results

-

Enhance the performance of your Axxiom/Schmidt blast pot with high-quality lids and screens designed to protect your abrasive media from debris and moisture contamination. Available individually or in convenient sets, these durable accessories are offered in multiple sizes to fit your blast machine.

- Compatible with Axxiom/Schmidt blast machines as well as other brands with standard 12", 18", 24", and 36" diameters

- 1/4" mesh screen prevents large debris from entering the pot

- Lid helps shield media from moisture, rain, and site contaminants

- Available in individual components or bundled as a lid & screen set

- Color options: White, Black, or BlastOne Orange

-

DM201150190

- Industrial-Grade Muffler for Pressure-Release Blast Pots

- Safer and much longer lasting than 'throw-away' mufflers

- Reduces blow-down noise to approx. 110 dB.

- Intercepts abrasive that may otherwise escape when depressurizing

- Sold as a Field-Installable Retrofit Kit including;

- VBS II Exhaust Muffler

- Mounting Bracket (Attaches to Combo Valve)

- Any required fittings

- Does not include a new Blow Down hose

- Genuine Products - Manufactured by Axxiom Manufacturing/Schmidt

- Note: This muffler comes standard on Schmidt combo-micro blast pots from BlastOne.

- Also available for Pressure-Hold systems here

DM201150190- Industrial-Grade Muffler for Pressure-Release Blast Pots

- Safer and much longer lasting than 'throw-away' mufflers

- Reduces blow-down noise to approx. 110 dB.

- Intercepts abrasive that may otherwise escape when depressurizing

- Sold as a Field-Installable Retrofit Kit including;

- VBS II Exhaust Muffler

- Mounting Bracket (Attaches to Combo Valve)

- Any required fittings

- Does not include a new Blow Down hose

- Genuine Products - Manufactured by Axxiom Manufacturing/Schmidt

- Note: This muffler comes standard on Schmidt combo-micro blast pots from BlastOne.

- Also available for Pressure-Hold systems here

-

DM201150191

- Industrial-Grade Muffler for Manual Blow-Down (Pressure-hold) Blast Pots with Thompson valve or TeraValve

- Safer and much longer lasting than 'throw-away' mufflers

- Reduces blow-down noise to approximately 110 dB

- Intercepts abrasive that may otherwise escape when depressurizing

- Sold as a Field-Installable Retrofit Kit including;

- VBS II Exhaust Muffler

- Mounting Bracket (Goes on blast pot leg)

- Blowdown Hose Assembly

- Ball Valve and required fittings

- Genuine Products - Manufactured by Axxiom Manufacturing/Schmidt

- Also available for Pressure-Release pots here

DM201150191- Industrial-Grade Muffler for Manual Blow-Down (Pressure-hold) Blast Pots with Thompson valve or TeraValve

- Safer and much longer lasting than 'throw-away' mufflers

- Reduces blow-down noise to approximately 110 dB

- Intercepts abrasive that may otherwise escape when depressurizing

- Sold as a Field-Installable Retrofit Kit including;

- VBS II Exhaust Muffler

- Mounting Bracket (Goes on blast pot leg)

- Blowdown Hose Assembly

- Ball Valve and required fittings

- Genuine Products - Manufactured by Axxiom Manufacturing/Schmidt

- Also available for Pressure-Release pots here

-

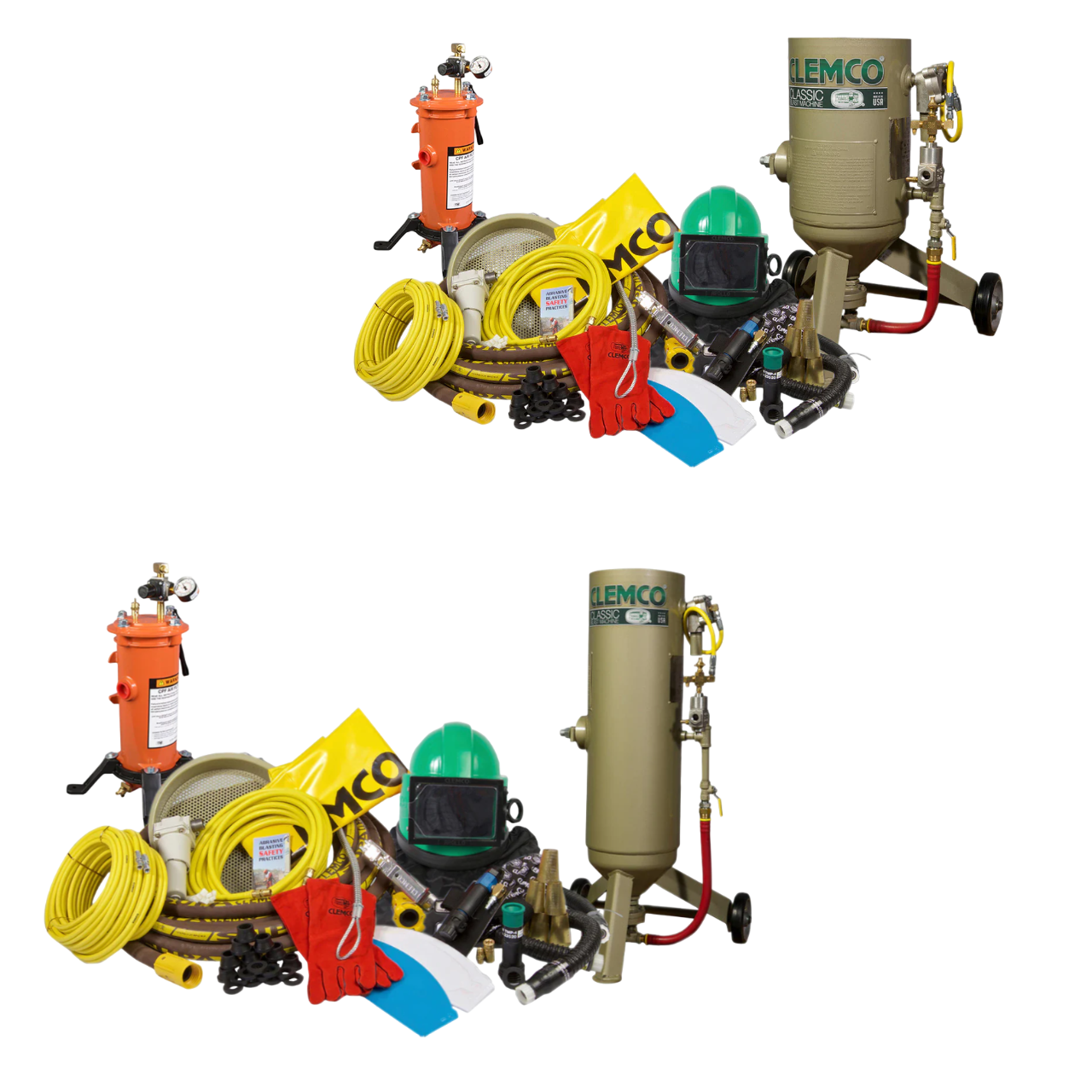

Clemco Industries is the world's largest manufacturer of air-powered blasting equipment. It is over 80 years old, being founded in 1941. The Classic line from Clemco is the original design and offers the largest size selection. This section includes the highly portable 3 cubic foot 1648 series. Similar to the 6 CF Clemco Classic Blast Machines, these smaller units (16" diameter) offer the following:

- Pneumatic controls with separate inlet & outlet valves (electric controls offered on the Contractor series or by special quote only)

- Choice of pressure-release or pressure hold

- Choice of metering valves including FSV, MQV, AQV, GW

- Pots with controls only, OR packages including accessories such as Apollo 600 respirators, blast hose & nozzles, breathing air system (minus the CO monitor, available separately) and more

-

The Schmidt® AmphiBlast™ Lite 3.5 is a compact, mobile wet/dry abrasive blasting system that delivers precision control, minimal water usage, and high efficiency. Featuring easy mode switching and a dry abrasive tank design, this unit offers cleaner operation and superior performance in both standard blasting and Softwash™ applications. Available Options:

- Models with or without the onboard 15 gallon water tank

- Electric or Pneumatic controls - both with the latest G3 Trigger deadman

- Standard abrasives only, or with Multi-Media technology, allowing the use of all medias regardless of weight, including soda

-

Clemco Industries is the world's largest manufacturer of air-powered blasting equipment. It is over 80 years old, being founded in 1941. The Classic line from Clemco is the original design and offers the largest size selection. Excellent for small blasting projects where portability is key, this section includes the 0.5CF (1028 series) and 1.0CF (1042 series). Similar to their larger sisters, these 10" diameter smaller units offer many of the same features including:

- Pneumatic controls with separate inlet & outlet valves, but with ½" piping instead of 1-¼".

- The compact ½" Manual Sand Valve (MSV) - similar to the FSV but specially designed for these smaller units. Note: This valve is designed for expendable mineral and slag abrasives, and is not suited for fine mesh or glass abrasives.

- Pots with TLR-50 controls only, OR full packages including accessories such as the Apollo 20 DLX w/constant flow respirator, 25' blast hose & #4 nozzle, breathing air system (minus the CO monitor, available separately), drop-in screen and more.

- Note: These pots are offered in pressure-release only.

-

BlastOne offers a selection of popular replacement Filter Cartridges for most dust collectors. Selected details are as follows:

- Applications include Mobile Dust Collector Units, Blast Room Dust Collectors, and Cabinet Dust Collectors.

- Base media types available:

- 100% cellulose. Economy general purpose application. Merv 10 rated. Can be used in applications where filters must be changed according to a shorter schedule.

- 80/20 cellulose/poly. General purpose filtration with increased resistance to moist air. Merv 10.

- Spunbond. This 100% polyester media is Merv 10 and highly moisture resistant. It has somewhat less filtration efficiency due to the lower square footage inherent in this media. Excellent for applications where the moisture in the pulse air supply is elevated.

- Optional treatments for all media:

- Nano. This high-performance treatment boosts the MERV rating to 15, and can be combined with any base media. Besides the better efficiency, the longer life it provides often pays for itself in fewer filter changeouts. This treatment is required in applications involving hazardous lead dust.

- ePFTE. This ultra-high MERV 16+ treatment can sometimes be used as a substitute for separate HEPA filtration, and provides protection against extremely fine hazards such as asbestos.

- Flame Resistance. FR treatment is available for most filter types.

-

ASEPDOD3When using the Sponge-Jet B-Vac integrated blast system, using a stand-alone cyclonic separator in-line with the vacuum hose is often desireable. This unit can be placed next to the B-Vac and reduces the dust load on the B-Vac dust filter. The Sponge-Jet dropout drum can also be used in any sponge media recovery application. It comes with a 3 inch vacuum hose port and is can be used with a vacuum hose fitted with a cam lock fitting. Vacuum hose, camlock fittings, and vacuum pick-up tools available separately. Note: Due to our distribution agreement with Sponge-Jet, pricing is not shown on our website. Contact us for fast, competitive pricing or send in the web form quote request.ASEPDOD3When using the Sponge-Jet B-Vac integrated blast system, using a stand-alone cyclonic separator in-line with the vacuum hose is often desireable. This unit can be placed next to the B-Vac and reduces the dust load on the B-Vac dust filter. The Sponge-Jet dropout drum can also be used in any sponge media recovery application. It comes with a 3 inch vacuum hose port and is can be used with a vacuum hose fitted with a cam lock fitting. Vacuum hose, camlock fittings, and vacuum pick-up tools available separately. Note: Due to our distribution agreement with Sponge-Jet, pricing is not shown on our website. Contact us for fast, competitive pricing or send in the web form quote request.

-

ASEPMRHThis Media Recovery Hopper is used in vacuum recovery of sponge media. Vacuum hose and vacuum tools available separately - see You May Also Like below. Note: Due to our distribution agreement with Sponge-Jet, pricing is not shown on our website. Contact us for fast, competitive pricing or send in the web form quote request. This product will be less costly if purchased with the initial blast equipment rather than on it's own.ASEPMRHThis Media Recovery Hopper is used in vacuum recovery of sponge media. Vacuum hose and vacuum tools available separately - see You May Also Like below. Note: Due to our distribution agreement with Sponge-Jet, pricing is not shown on our website. Contact us for fast, competitive pricing or send in the web form quote request. This product will be less costly if purchased with the initial blast equipment rather than on it's own.

-

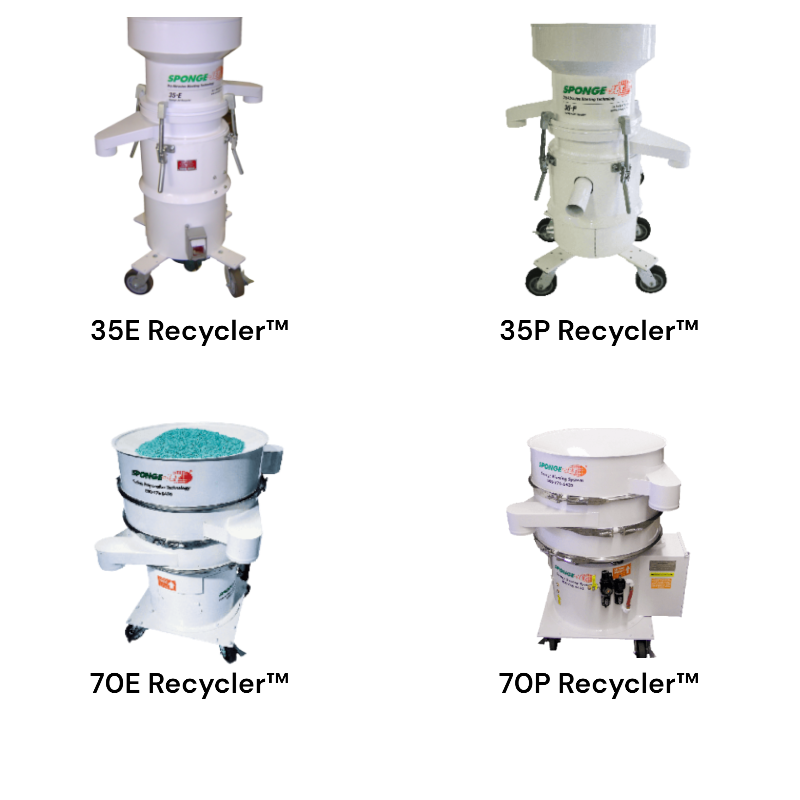

Recycler screens are available in various mesh sizes, allowing optimization of dust removal or media recycles, whatever your application requires. These screens are for the 70 series recyclers. Screens are also available for the 35 series - enquire. NOTE: Due to our distribution agreement with Sponge-Jet, pricing is not shown on our website. Contact us for fast, competitive pricing or sent your request via our web quote link.

-

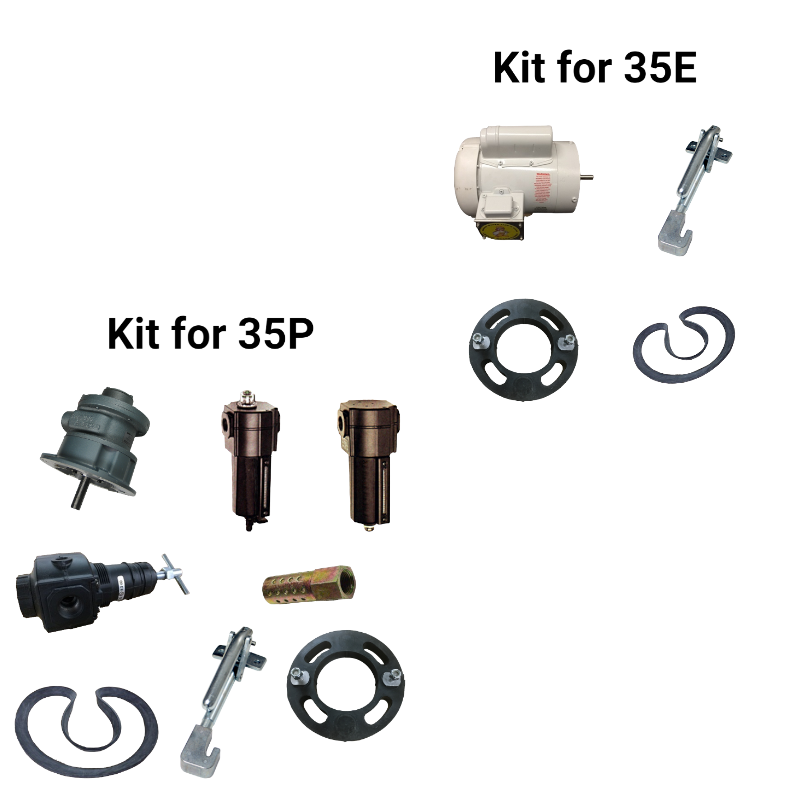

Sponge-Jet offers a robust repair kit for each of their recycler models. Pictured are the kits for the 35 series units (other series kits are similar with the appropriate substitutions). Included items are as follows:

- Electric Recycler kits:

- Electric motor

- Flexible coupling

- 4 flat gaskets

- 2 clamps

- Pneumatic Recycler kits:

- Air motor

- Lubricator

- Moisture separator

- Muffler

- Filter

- Flexible coupling

- 4 gaskets

- 2 clamps

- Electric Recycler kits:

-

Tite-Space nozzles are angle nozzles, designed for use in areas that are especially difficult to access, and feature:

- 3/8" NPT Thread in either Male or Female configuration

- Male version has brass threads and requires a minimum opening clearance of 1". This version is 1-7/8" long.

- Female version has steel threads and requires a minimum opening clearance of only ¾". This version is 3-1/8" long.

- These nozzles are often used in conjunction with our Tite Space Invader Blasting Kit, available here

- Angle options include:

- 45° & 60° forward blast

- 90° right angle blast

- 135° reverse blast

- Some options available in double, triple or quad orifices in addition to single.

- Note: Using nozzles with multiple orifices will multiply the compressed air CFM requirement accordingly.

- Stock version uses tungsten carbide lining.

-

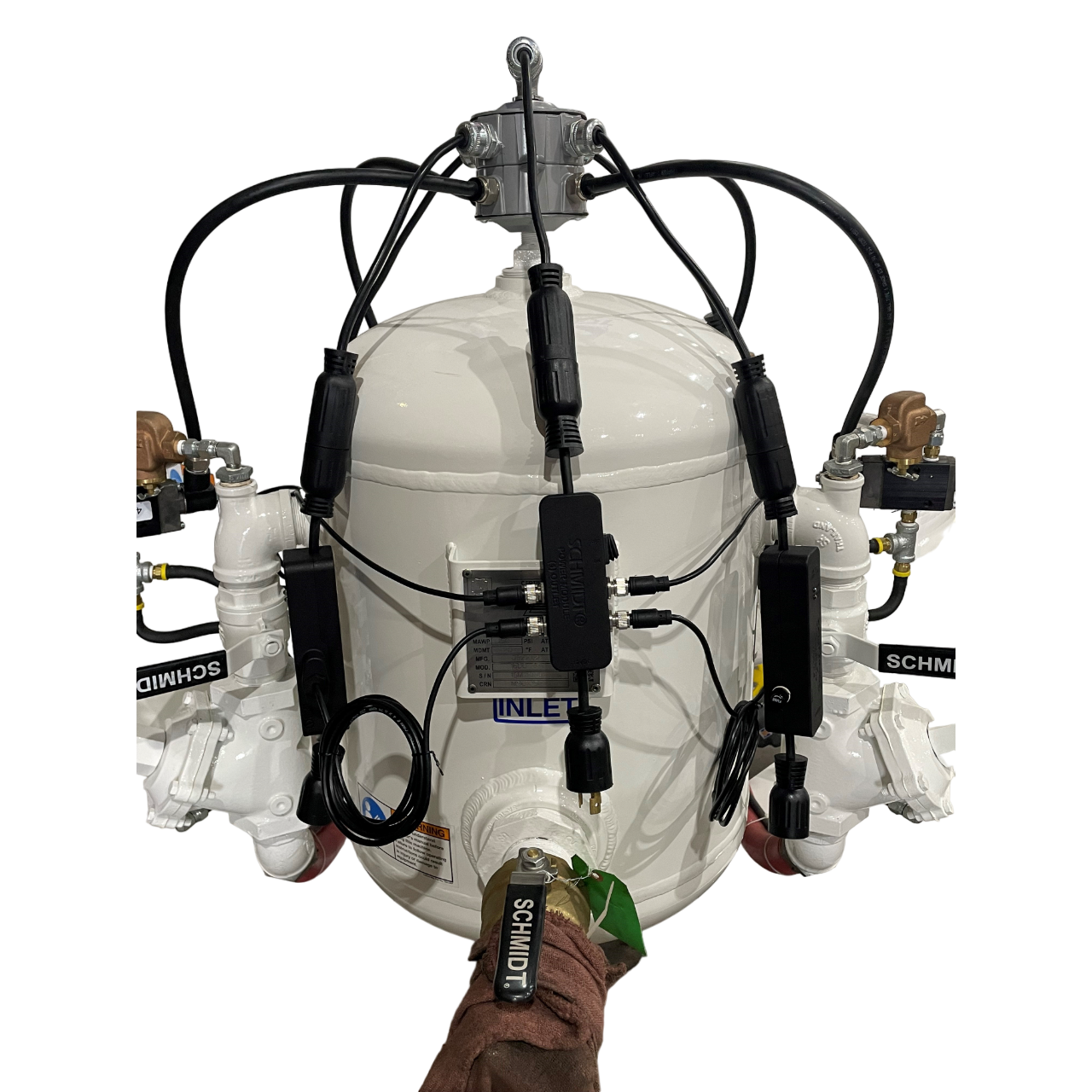

The SmartSPARKTM Short Proof Deadman Control System is enhancing blaster safety in all blast operations. Designed to address inadvertent activations caused by electrical shorts in deadman control lines, the SmartSPARK Deadman System keeps your blasters safe. The SmartSPARK Deadman and Controls has a closed loop system, that will detect an electrical short in the deadman line and shut off the blast pot instantly.

- Designed to quickly retrofit onto existing Schmidt blast pots with electrical deadman controls

- Reduces the likelihood of accidental start-ups by detecting and responding to electrical shorts

- 2 models avaliable - single outlet and 4-operator outlet.

- Ideal for blastrooms that have steel grating and blast sites where multiple operators are working simultaneously.

Our Blasting & UHP Site Equipment category offers everything you need for efficient and effective surface preparation. For abrasive blasting, we supply a variety of blasting pots, nozzles, and blast hoses that ensure consistent media flow and superior performance. If you’re working with ultra-high-pressure water blasting, our UHP pumps and water jetting accessories are engineered for maximum power and precision, making them ideal for removing coatings, rust, and other heavy contaminants. Whether you’re tackling a large industrial project or a specialized cleaning job, our equipment is designed to meet the highest standards of safety and efficiency. Need assistance? Our team is here to provide expert guidance on selecting the best tools for your needs.

My Account

My Account

Blast Equipment

Blast Equipment Blast Nozzles

Blast Nozzles Blast Equipment Parts

Blast Equipment Parts Blast / Air Hose & Couplings

Blast / Air Hose & Couplings Portable Lighting

Portable Lighting Air Dryers

Air Dryers Ventilation & Other Field Equipment

Ventilation & Other Field Equipment UHP & Pressure Washing Equipment

UHP & Pressure Washing Equipment