Abrasives

Showing 31–37 of 37 results

-

- Available in fine, medium, coarse, and extra coarse grit size

- Individual bag or Bulk bag available

- Approved to SSPC AB1 Standard

- Shape - Angular/Sub-Angular

- Mohs Hardness of 7

- Bulk Density of 85 to 105 lbs/ft2

- Sold by the pallet (pallet minimum)

- Abrasive cannot be ordered online at this time

-

- Corn Cob abrasive is ideal for deburring and polishing.

- Used to remove mold, smoke and fire damage

- Can be used on operating machinery, will not damage glass or rubber.

- Natural, Non-sparking abrasive

- Sold by the pallet (pallet minimum)

- Abrasive cannot be ordered online at this time

-

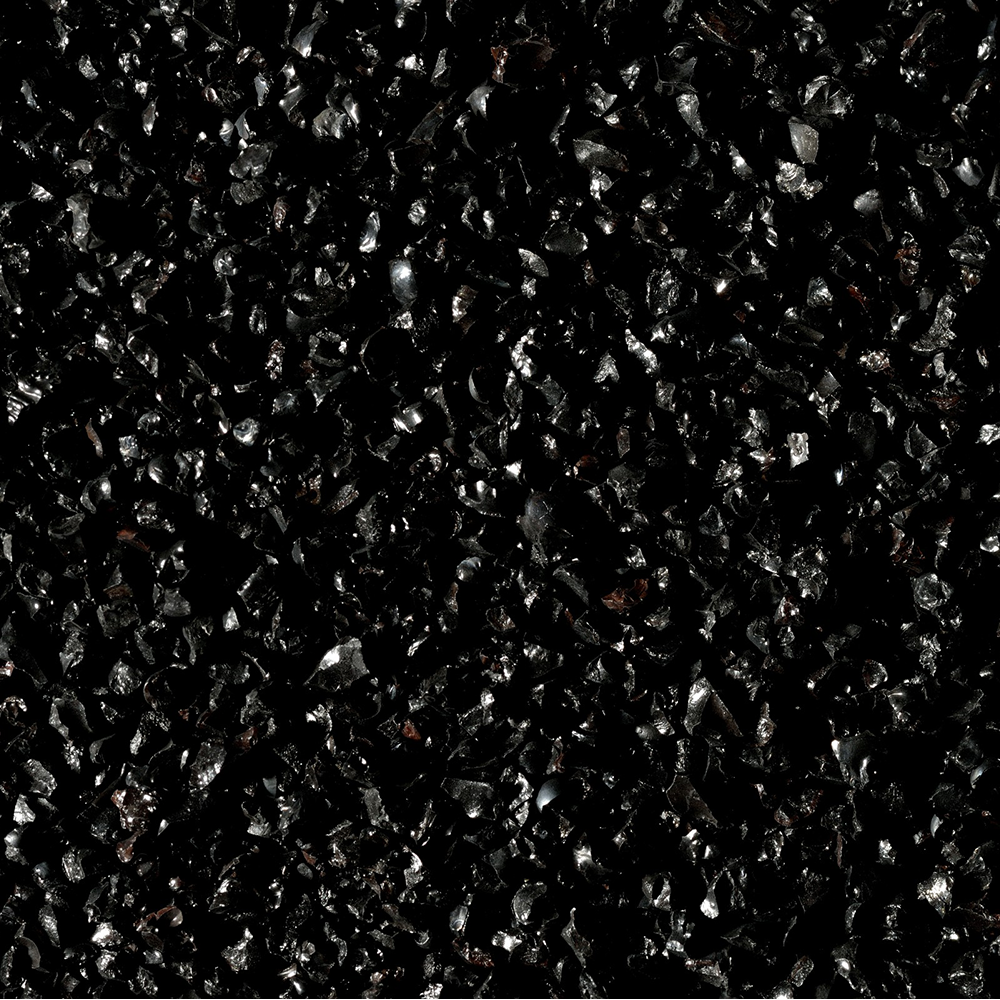

GXMB4400

- Designed to remove Coating Thickness: 20-50 ml

- Unique formulation, ideal for blasting marine offshore, oil and gas, shipyards

- Typically used where heavy coatings and rust are existing

- Blend has large particles designed to effectively remove heavy coatings and finer particles to thoroughly clean the pits and surface.

- Expected Profile 2.5 - 4.0 ml

- Abrasive Consumption 2.5 - 5.0 lb/ft2

- Blasting Rates up to 370ft2 /hr

- Sold by the pallet (pallet minimum)

- Abrasive cannot be ordered online at this time

GXMB4400- Designed to remove Coating Thickness: 20-50 ml

- Unique formulation, ideal for blasting marine offshore, oil and gas, shipyards

- Typically used where heavy coatings and rust are existing

- Blend has large particles designed to effectively remove heavy coatings and finer particles to thoroughly clean the pits and surface.

- Expected Profile 2.5 - 4.0 ml

- Abrasive Consumption 2.5 - 5.0 lb/ft2

- Blasting Rates up to 370ft2 /hr

- Sold by the pallet (pallet minimum)

- Abrasive cannot be ordered online at this time

-

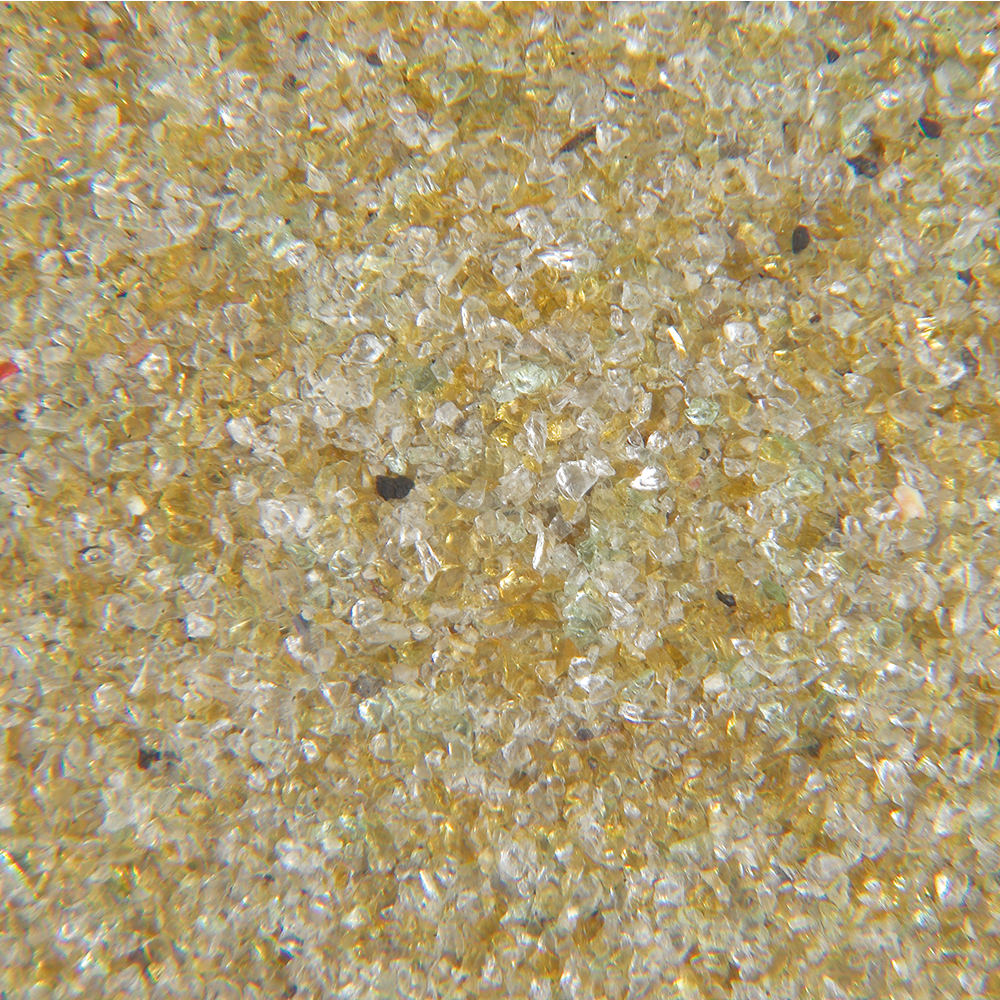

- Effective Replacement for Dupont StarBlast

- Single use mineral sand abrasive blast media.

- Typical applications include: Mill scale, light rust and new steel

- Mohs hardness of around 7

- Expected profile range of 1-2mils

- Blasting Speeds between 75 - 150ft2/hr

- Typically has a high dust burden

- Sold by the pallet (pallet minimum)

- Abrasive cannot be ordered online at this time

-

The Steel Shot Blasting Abrasive is a highly durable and long-lasting peening media, ideally suited for use in airless wheel blast machines for applications like cleaning foundry castings, surface polishing, shot peening, and concrete floor preparation. Available in a variety of grades and sizes, this steel shot is designed for a high-quality performance, conforming to SAE J444, SAE J827, SFSA 20-66 standards, and can be recycled multiple times, offering an economical and effective solution for shot blasting needs.

- Steel shot - manufactured hypereutectoid, metal spheres used in airless centrifugal wheel blast machines to clean foundry castings, surface polishing and shot peening

- Also used in portable trackblast airless wheel blast machines for concrete floor preparation, blasting ship decks and profiling

- Quality Steel Shot is very long lasting

- Steel Shot can be recycled many times

- Hardness: 40-50 HRc. Other hardness's of steel shot are available on request

- Special, Stainless Steel Shot and High Hardness, Milspec (Military Specification Peening Steel Shot) specification shots available

- Manufactured to conform to: SAE J444, SAE J827, SFSA 20-66

- Steel Shot is packed in 25kg bags, drums or bulk bags

-

Stainless Steel Shot

- Manufactured stainless steel shot abrasive

- Can be recycled many times

- Stainless Steel Abrasives are also used in applications where there can be no ferrous contamination

- Used mainly in an air-blast application to create a specific desired finish or where a non-ferrous abrasive is required

- Packed in 25kg bags

- Made by Ervin

-

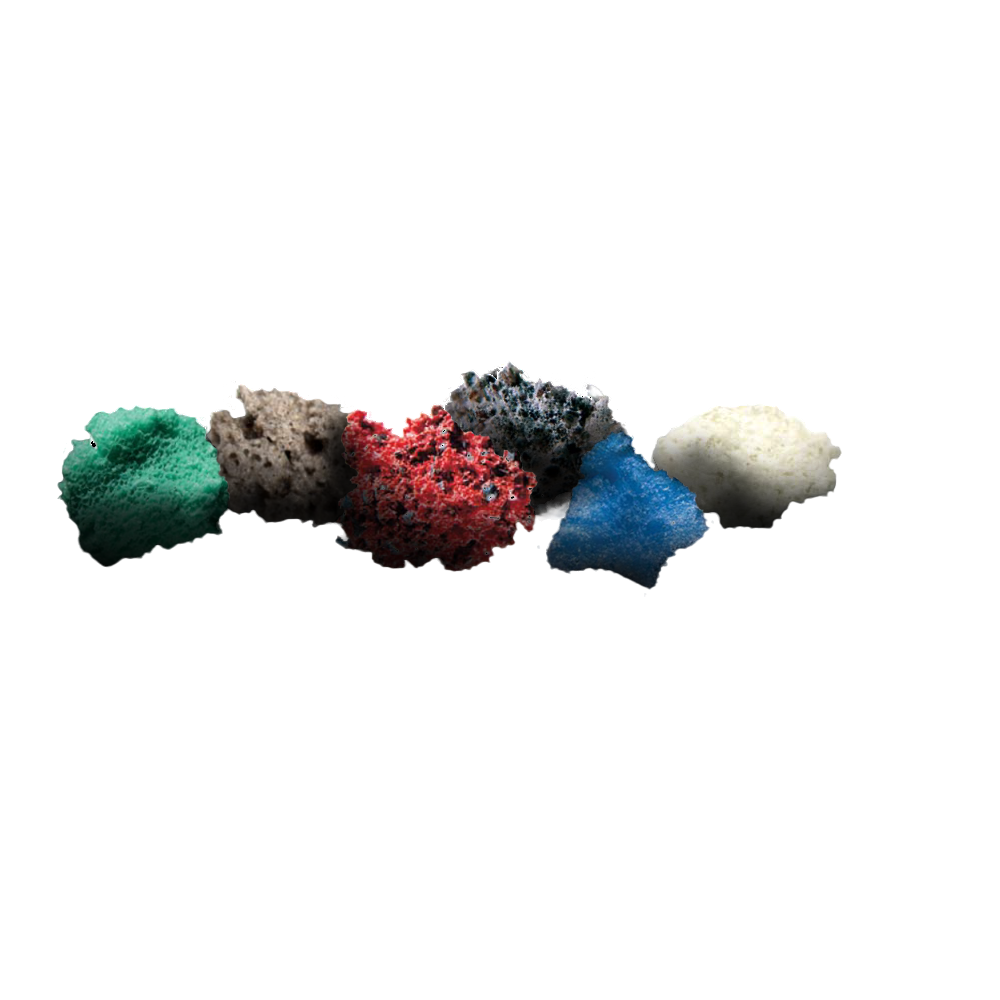

- An efficient abrasive with a lighter touch

- Ideal for softer substrates - wood, aluminum, brass and fiberglass

- Can also be used to de-burr, polish or remove smoke damage

- Sold by the pallet (pallet minimum)

- Abrasive cannot be ordered online at this time

In addition to offering premium abrasives, we provide expert advice to help you achieve optimal results in your sandblasting projects. Learn about the different types of abrasives, including crushed glass, garnet, and aluminum oxide, and how to select the appropriate grit size for your specific application. Our team is committed to helping you make informed decisions, ensuring you choose the right product for maximum efficiency and performance. Don’t hesitate to explore related products or contact our staff for assistance with your purchase.

My Account

My Account

Garnet Abrasives

Garnet Abrasives Aluminum Oxide

Aluminum Oxide Glass Blasting Abrasive

Glass Blasting Abrasive Slag Abrasives

Slag Abrasives Sponge Abrasives

Sponge Abrasives Staurolite Blasting Abrasive

Staurolite Blasting Abrasive Steel Abrasives

Steel Abrasives Corn Cob Blasting Abrasive

Corn Cob Blasting Abrasive Armex Soda Blasting Abrasive

Armex Soda Blasting Abrasive Walnut Shell Blasting Abrasive

Walnut Shell Blasting Abrasive