Blasting, UHP & Site Equipment

Showing 31–45 of 646 results

-

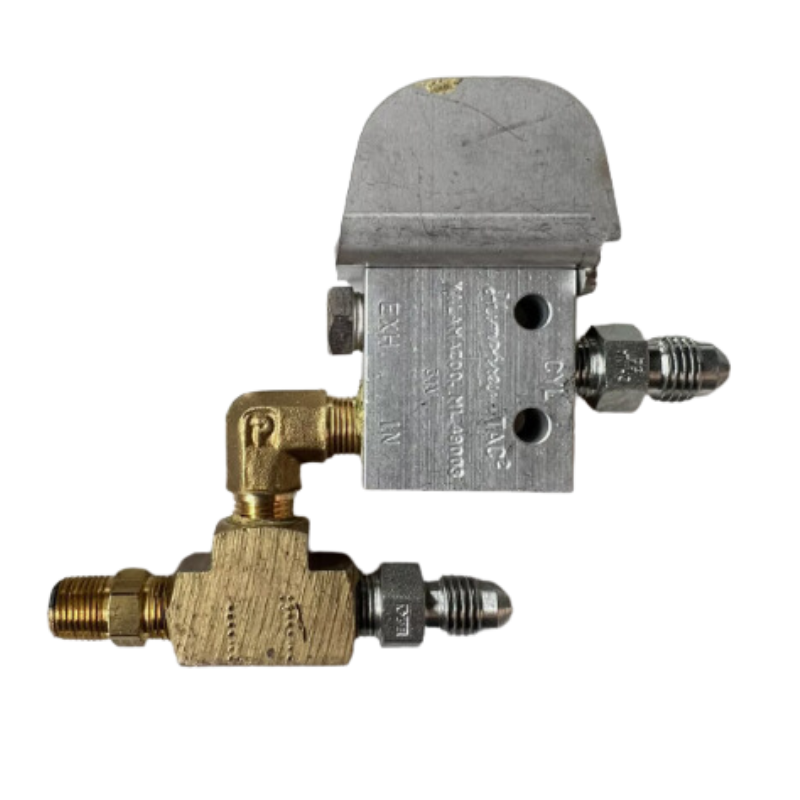

DMRLX07654The Clemco 07564 replacement abrasive cut-off assembly fits Clemco 10565 pneumatic deadman handles on blast machines equipped with abrasive cut-off control.

- Replacement abrasive cut-off assembly

- Fits Clemco 10565 pneumatic deadman handles

- For blast machines with abrasive cut-off functionality

- OEM Clemco part

- SKU: DMRLX07564, MPN 07564

DMRLX07654The Clemco 07564 replacement abrasive cut-off assembly fits Clemco 10565 pneumatic deadman handles on blast machines equipped with abrasive cut-off control.- Replacement abrasive cut-off assembly

- Fits Clemco 10565 pneumatic deadman handles

- For blast machines with abrasive cut-off functionality

- OEM Clemco part

- SKU: DMRLX07564, MPN 07564

-

Galvanized tee fittings with NPT female threads are built for plumbing, fabrication, and repair work. These tees connect three lines and are available in equal size or reducing variations for different pipe runs.

- Galvanized finish resists rust and corrosion

- NPT, FFF (Female x Female x Female threads)

- Available in equal tee or reducing tee options

- Reliable for plumbing, fabrication, and shop repairs

-

The BlastOne Infinity Blast Nozzle is the latest proprietary advancement in blasting nozzle technology from the innovators behind the SnakeBite silenced nozzle. Engineered for durability and precision, this general-purpose nozzle delivers extended wear life and a consistent blast pattern across a wide range of industrial applications.

- BlastOne’s newest innovation in blasting nozzle design

- Approximately 6" overall length for versatile use. NOTE: For applications with sufficient space, hyper performance is available in our Infinity XL blast nozzle.

- The proprietary design of the silicon nitride liner minimizes internal turbulence

- Urethane outer jacket provides rugged durability

- Jam-resistant contractor threads ensure easy installation

- Available in orifice sizes: #6, #7, and #8

- Delivers consistent blast pattern and reduced abrasive consumption

NOTE: Infinity nozzles are not compatible with water-ring attachments.

-

The BlastOne Infinity XL Performance Blast Nozzle is possibly the fastest blasting nozzle available, boasting a 35% performance increase over standard blast nozzles. This nozzle, which was designed to be high-speed with extended-wear, was engineered by the developers of the iconic SnakeBite silenced nozzle. Developed with an advanced extended venturi and space-age liner, this proprietary innovation maximizes blasting velocity and efficiency in demanding industrial environments.

- Increases blasting performance by 35% over standard blast nozzles

- Latest proprietary design from BlastOne’s nozzle technology line

- 11–13" overall length depending on orifice size. NOTE - for applications not needing the Hyper nozzle performance of the Infinity XL, our 6" long standard Infinity nozzle is excellent and is ideal where access is limited.

- Proprietary silicon nitride liner for low turbulence and long life

- Durable urethane jacket withstands harsh job conditions

- Contractor-grade threads resist jamming during use

- Available in orifice sizes: #6, #7, and #8

- NOTE: Infinity nozzles are not compatible with water-ring attachments.

-

Axxiom / Schmidt High Production work-horse for big dry-blast projects! Save time and money when doing large projects.

- Industrial Quality & Design - Manufactured by Schmidt to BlastOne specifications

- Long-life TeraValve metering valves - typically 4-outlets

- High-flow plumbing virtually eliminates pressure drop

- Huge abrasive capacity - Up to 160 cubic feet (aka 8-ton pot) holds half a truckload of garnet! Also available in 120cf, 60cf and 45cf sizes.

- Flexible configuration - Available with:

- Highway Trailer

- Yard Trailer

- Skid mount

- Shipping Legs (for mounting on your own equipment)

- Latest Latest-generation safety features

- HALOK® closure - impossible to open under pressure

- CEN muffler - reduces noise AND prevents freeze-up

- Anti-slip ladder rungs

- Available Performance Enhancing Options

- Bulk Bag Loading Rack - enhances safety while loading

- Hybrid - attached dryer saves space & setup time

- Vacuum loading - saves wait time for cranes where forklift loading of abrasive is prohibited

- Hour meters - management tool monitors nozzle time

- Industrial Quality & Design - Manufactured by Schmidt to BlastOne specifications

-

BlastOne's 160 CF Mega MistBlaster is the ultimate solution for professionals seeking flexibility in surface preparation. This advanced blast machine, exclusively designed by BlastOne, offers both wet and dry blasting capabilities, making it ideal for large projects where efficiency and versatility are paramount.

- Versatility. 4 functions available at the flip of a switch:

- MistBlasting / Wet (slurry) Blasting

- Traditional Dry Blasting

- Wash-down mode

- Blow-off mode

- Each outlet is independently controlled, giving even greater versatility.

- Capability. With its 4 outlets, this workhorse can power up to 4 operators OR a VertiDrive robotic blaster and manual blasting simultaneously.

- Huge capacity - As typically configured with 160 cubic feet (aka 8 Ton), this bulk pot holds half a truckload of garnet.

- Mount Options as follows:

- Highway Trailer

- Skid Mount

- Shipping Legs (for mounting on your own equipment)

- Available Cost Saving Option - We can convert your existing Schmidt® Dry bulk pot with to our Mega MistBlaster with our retrofit package. Available as a Limited version (without metering / air valves, for new pots) or as a Full version (with all valves, for used pots).

- Versatility. 4 functions available at the flip of a switch:

-

The Schmidt® 10 cf Blast Machine is engineered for extended blasting operations, offering increased abrasive capacity for longer run times between refills. It can be configured with wheels (the largest hand-portable size available with this option) for field work. Alternately, the increased capacity makes it an excellent choice for stationary applications in blast rooms. Key features of the Schmidt 10CF Blast Pot:

- Capacity of up to 1,500 lbs of garnet or 2,450 lbs of steel grit

- Extended blasting time reduces downtime for refills

- Configurable with single or dual outlet for one or two operators

- Available in portable (with wheels) or stationary configurations

- Offered with the following OEM abrasive metering valves:

- Combo/MicroValve III® (Pressure-Release)

- Thompson® Valve II (Pressure-Hold)

- TeraValve® XL (Pressure-Hold)

- Genuine Schmidt® product, made in USA by Axxiom Manufacturing

-

BMS1102TERASchmidt made-in-USA blast machine in a special ergonomic design.

- Dual Outlet for 2 operators.

- Unique short design - only 46 inches tall! Shorter than a standard 6.5 pot.

- Capacity of 11 cu ft, which equates to 1600lbs of a dense media like premium GMA Garnet

- Pressure Rating: 150psi

- TeraValve pressure-hold metering valves

- Blast Pot

- Pneumatic Deadman Control System comes with 2 sets of 50 feet of control line and handle

- Choice of inlet fitting in either 4-claw or Spud type. Spud will be supplied unless otherwise noted in Order Comments field.

BMS1102TERASchmidt made-in-USA blast machine in a special ergonomic design.- Dual Outlet for 2 operators.

- Unique short design - only 46 inches tall! Shorter than a standard 6.5 pot.

- Capacity of 11 cu ft, which equates to 1600lbs of a dense media like premium GMA Garnet

- Pressure Rating: 150psi

- TeraValve pressure-hold metering valves

- Blast Pot

- Pneumatic Deadman Control System comes with 2 sets of 50 feet of control line and handle

- Choice of inlet fitting in either 4-claw or Spud type. Spud will be supplied unless otherwise noted in Order Comments field.

-

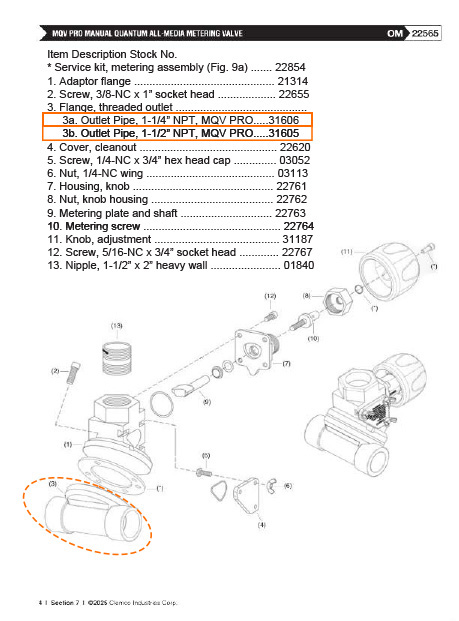

Clemco MQV-Pro Outlet Pipes are OEM replacement parts designed to fit the MQV-Pro metering valve only. Available in 1-1/4", and 1-1/2" sizes, each pipe ensures a proper abrasive flow path in pressure-release Clemco blast systems.

- OEM replacement outlet pipe for MQV-Pro metering valves only

- Used on Clemco pressure-release blast pots

- Restores abrasive flow from valve to hose

- MPNs:

- 31606 (1-1/4")

- 31605 (1-1/2")

-

BABL3101BOOTReplace your worn-out toggle boot with the durable 3101 Boot. Compatible with ADI and Western Technology ball-and-chain deadmans, it ensures reliable protection and longevity for your deadman switch. MPN: 3101 Boot SKU: BABL3101BOOTBABL3101BOOTReplace your worn-out toggle boot with the durable 3101 Boot. Compatible with ADI and Western Technology ball-and-chain deadmans, it ensures reliable protection and longevity for your deadman switch. MPN: 3101 Boot SKU: BABL3101BOOT

-

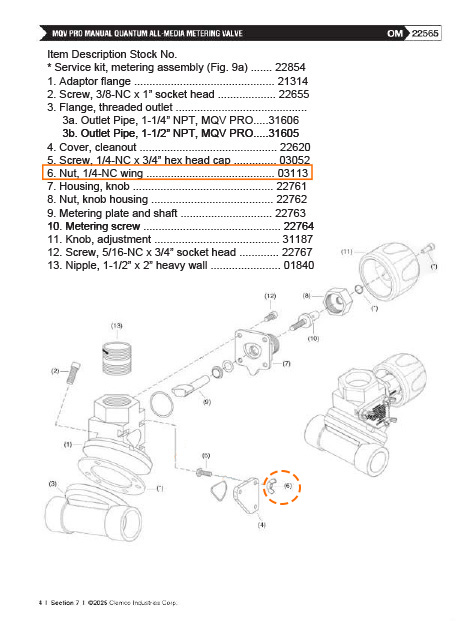

GVFSV1011Clemco 03113 Wing Nut is an OEM replacement part used to secure components in multiple Clemco metering valves and the BNP160 cabinet.

- OEM wing nut for Clemco metering valves and cabinets

- Fits Sentinel, MQV, MQV-Pro, and FSV valves

- Also used in BNP160 Tumble Blast Cabinet

- Secures valve components during operation

- SKU: BA03113

- MPN: 03113

GVFSV1011Clemco 03113 Wing Nut is an OEM replacement part used to secure components in multiple Clemco metering valves and the BNP160 cabinet.- OEM wing nut for Clemco metering valves and cabinets

- Fits Sentinel, MQV, MQV-Pro, and FSV valves

- Also used in BNP160 Tumble Blast Cabinet

- Secures valve components during operation

- SKU: BA03113

- MPN: 03113

-

The Schmidt® 20cf Blast Machine is engineered for extended blasting operations, offering increased abrasive capacity for longer run times between refills.

The increased capacity makes it an excellent choice for stationary applications in blast rooms.

Key features of the Schmidt 20 c.f. Blast Pot:

- Capacity of up to 3,000 lbs of garnet or 4,900 lbs of steel grit

- Extended blasting time reduces downtime for refills

- Configurable with single or dual outlet for one or two operators

- Comes in a stationary configuration and includes lifting eyes

- Supplied with premium Schmidt Pressure-Hold abrasive metering valves, including:

- Thompson® Valve II (with urethane or tungsten carbide sleeves), or

- TeraValve® XL

- Genuine OEM Schmidt® product, made in USA by Axxiom Manufacturing

-

The Schmidt 3.5cf blast pot offers a perfect mid-sized solution for abrasive blasting projects that are too large for a 1.5cf machine but too tight for a full-size 6.5cf unit. Built with durable, industrial-grade construction, this portable system provides a full 150 PSI working pressure and a range of valve and control options to fit different blasting environments.

- 3.5 cubic foot capacity, ideal for mid-size blasting projects

- Heavy-duty construction with full 150 PSI working pressure

- Choice of abrasive metering valves: Combo/MicroValve III, Thompson II Valve, or TeraValve

- Available with pneumatic or electric control systems for project-specific needs

- Genuine Schmidt® product, manufactured by Axxiom Manufacturing

-

VCBRS35FREE Shipping 30 Day Money-Back Guarantee | Free Returns 90 Day Manufacturer Warranty

- Abrasive holding capacity of 3.5 cu ft

- Blasting rate up to 40 ft2 per hour

- Compressed Air Requirement 750 cfm

- Includes fork pockets

- Can be wheel mounted for increased jobsite maneuverability

- Recirculating full size blast & recovery unit

- 100% compressed air driven - no electricity required

VCBRS35FREE Shipping 30 Day Money-Back Guarantee | Free Returns 90 Day Manufacturer Warranty- Abrasive holding capacity of 3.5 cu ft

- Blasting rate up to 40 ft2 per hour

- Compressed Air Requirement 750 cfm

- Includes fork pockets

- Can be wheel mounted for increased jobsite maneuverability

- Recirculating full size blast & recovery unit

- 100% compressed air driven - no electricity required

-

The Schmidt 1.5cf 'Handy Man' blast pot delivers industrial-grade performance in a compact, highly portable design, ideal for spot-work, small blasting projects, and areas where larger pots can't fit. Built with the same rugged construction as full-size models, it offers full 150 PSI working pressure and features precision abrasive metering valves.

- 1.5 cubic foot capacity for small projects and confined areas

- Durable, heavy-duty construction for reliable operation

- Rated for a full working pressure of 150 PSI (10.3 bar)

- Genuine Schmidt® product, manufactured by Axxiom Manufacturing

Our Blasting & UHP Site Equipment category offers everything you need for efficient and effective surface preparation. For abrasive blasting, we supply a variety of blasting pots, nozzles, and blast hoses that ensure consistent media flow and superior performance. If you’re working with ultra-high-pressure water blasting, our UHP pumps and water jetting accessories are engineered for maximum power and precision, making them ideal for removing coatings, rust, and other heavy contaminants. Whether you’re tackling a large industrial project or a specialized cleaning job, our equipment is designed to meet the highest standards of safety and efficiency. Need assistance? Our team is here to provide expert guidance on selecting the best tools for your needs.

My Account

My Account

Blast Equipment

Blast Equipment Blast Nozzles

Blast Nozzles Blast Equipment Parts

Blast Equipment Parts Blast / Air Hose & Couplings

Blast / Air Hose & Couplings Portable Lighting

Portable Lighting Air Dryers

Air Dryers Ventilation & Other Field Equipment

Ventilation & Other Field Equipment UHP & Pressure Washing Equipment

UHP & Pressure Washing Equipment