Blast Equipment Parts

Showing 196–210 of 373 results

-

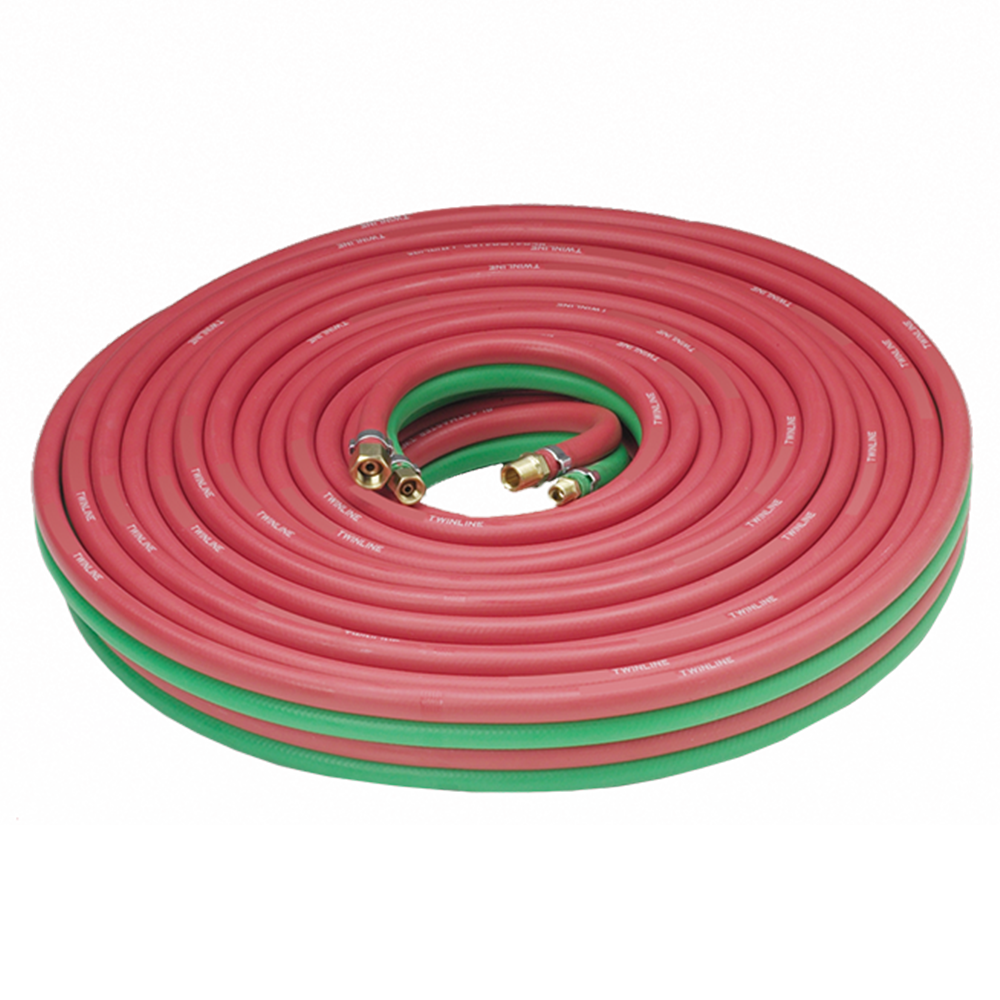

AHRMS4055AVAILABLE FOR RENTAL OR PURCHASE The "Twin line Deadman Control Hose" (SKU: AHRMS4055) offers a safe, heavy-duty solution for pneumatic deadman controls. Bonded and color-coded for enhanced safety, it is available for rental or purchase.

- Bonded, heavy duty, twin rubber hose, color coded for safety

- Used to supply air to the deadman handle which is used to signal a "blast" return charge of air to the blast pot control valves

- Always replace the hose at the first sign of wear, this is a safety deadman control item.

- Fitted standard with male-female threaded connectors

- 1/4" (6 mm) connectors on 'supply' red hose

- 1/8" (3 mm) connectors on 'return' green hose

- 55 ft length

- Please Request Rental Pricing

AHRMS4055AVAILABLE FOR RENTAL OR PURCHASE The "Twin line Deadman Control Hose" (SKU: AHRMS4055) offers a safe, heavy-duty solution for pneumatic deadman controls. Bonded and color-coded for enhanced safety, it is available for rental or purchase.- Bonded, heavy duty, twin rubber hose, color coded for safety

- Used to supply air to the deadman handle which is used to signal a "blast" return charge of air to the blast pot control valves

- Always replace the hose at the first sign of wear, this is a safety deadman control item.

- Fitted standard with male-female threaded connectors

- 1/4" (6 mm) connectors on 'supply' red hose

- 1/8" (3 mm) connectors on 'return' green hose

- 55 ft length

- Please Request Rental Pricing

-

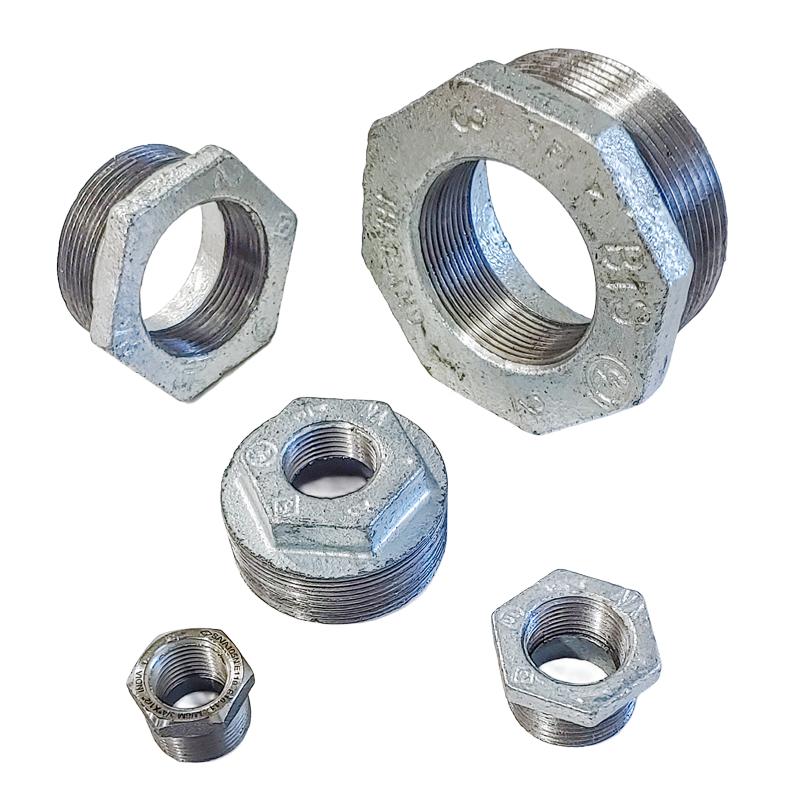

These galvanized pipe fittings, known as reducing bushings, hex bushings or reducer bushings, are NPT threaded and are used to connect pipes of different sizes.

- Galvanized malleable iron for strength and corrosion resistance

- Hex body for easy wrench tightening

- NPT threads for a tight, reliable seal

- Available in many male-to-female size combinations

- Stainless steel and other options available on request

-

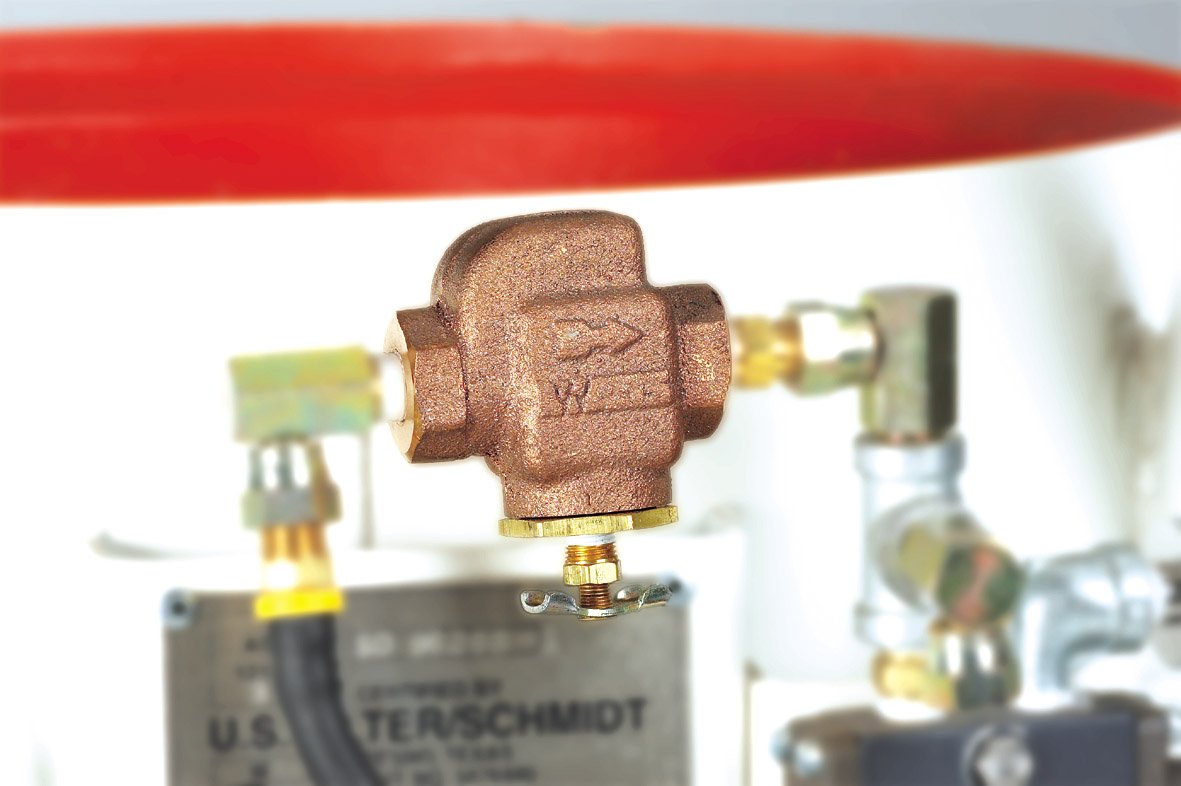

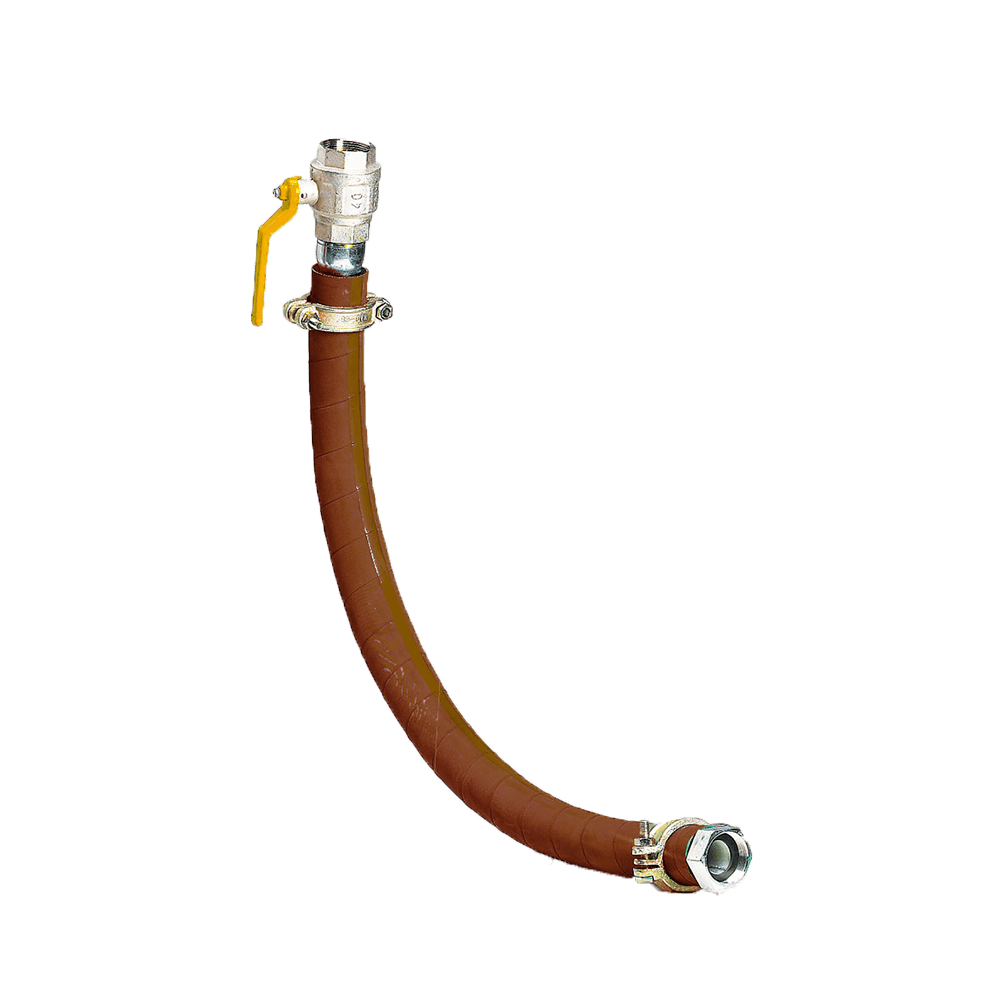

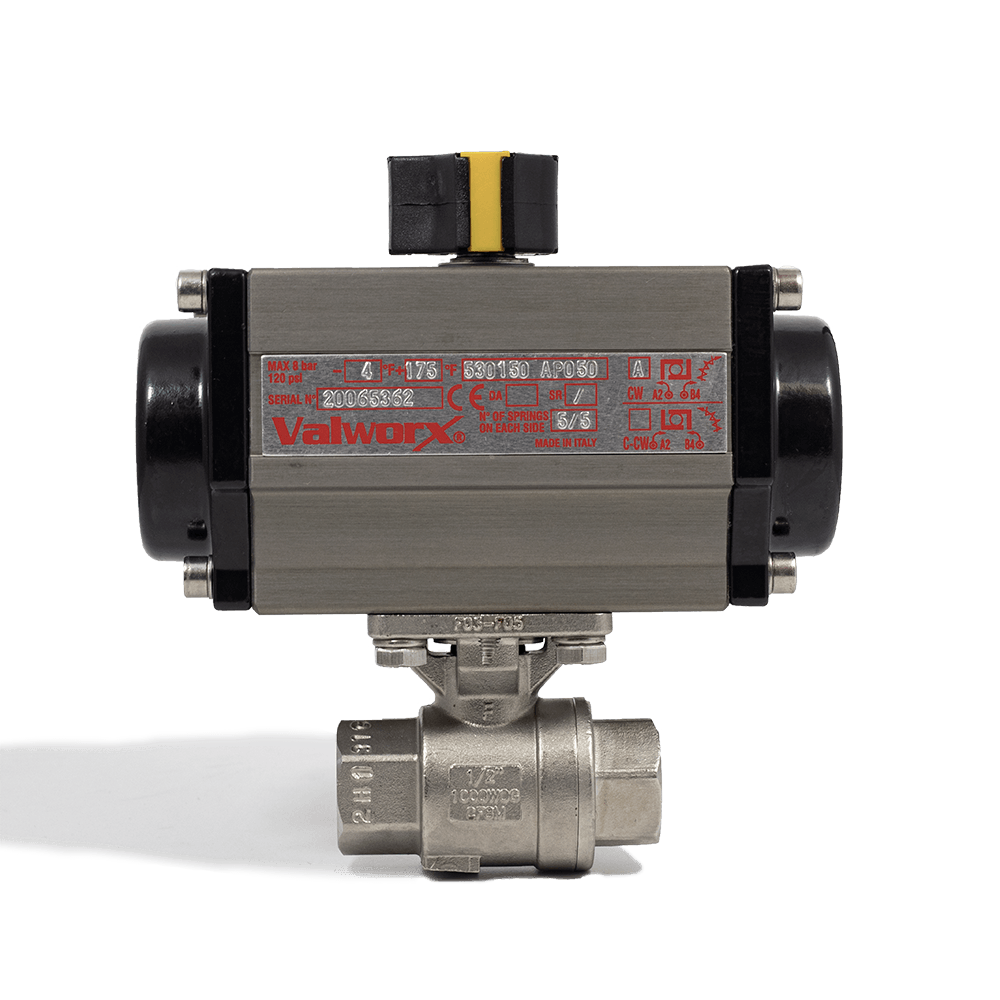

- Hi-flow Blast Pot Pusherline Kit

- Used on Blast Pots between the air control valves and the metering valve

- Sold as a complete assembly Including

- Pusherline Air Hose

- Ball valve

- Nut and tail fittings with bolt style clamps for in-field installation

- Connects to Metering Valve threaded nipple

-

GV01990

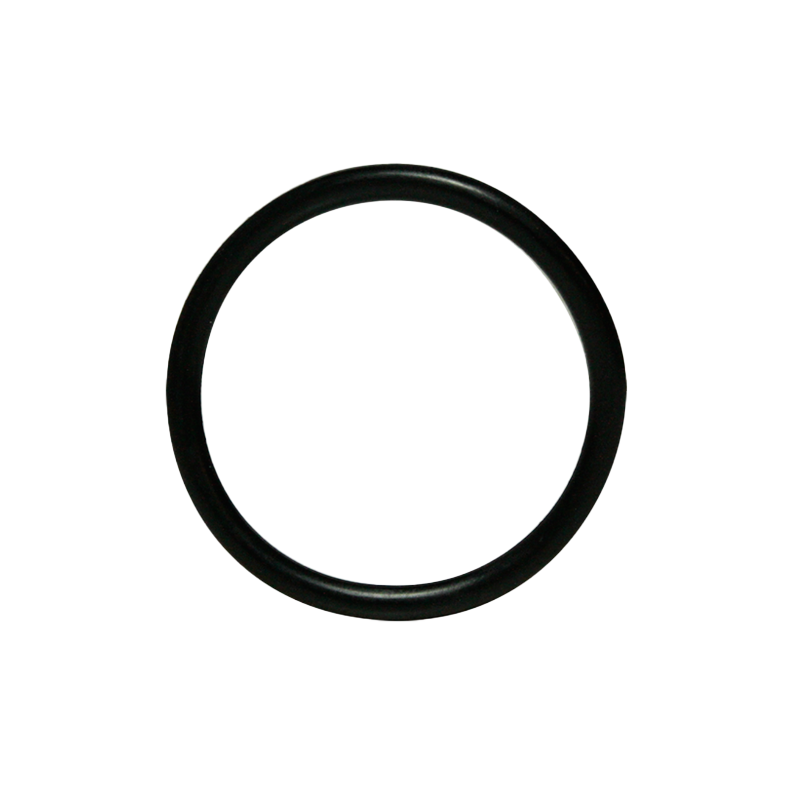

BlastOne has the parts to maintain your Clemco® blast equipment. This is the replacement 1-¾" O-ring for multiple Clemco valves.

GV01990BlastOne has the parts to maintain your Clemco® blast equipment. This is the replacement 1-¾" O-ring for multiple Clemco valves.

-

DMECK2999

- 24 ft cable with alligator clips

- Connects directly to a battery to supply 12 volt power for deadman controls

- Deadman cable is fitted with a 2-Pin TwistLok plug connector for connecting to Deadman controls on the blast pot

DMECK2999- 24 ft cable with alligator clips

- Connects directly to a battery to supply 12 volt power for deadman controls

- Deadman cable is fitted with a 2-Pin TwistLok plug connector for connecting to Deadman controls on the blast pot

-

DM2152ACRK

- Pneumatic Complete Retrofit kit includes:

- Triple-line coupled remote control hose

- Control hose connections for air supply

- Auto air valve and Thompson Valve II metering valve

- Pneumatic push-pull abrasive on-off switch

- Response deadman handle

DM2152ACRK- Pneumatic Complete Retrofit kit includes:

- Triple-line coupled remote control hose

- Control hose connections for air supply

- Auto air valve and Thompson Valve II metering valve

- Pneumatic push-pull abrasive on-off switch

- Response deadman handle

-

- Compatible with a wide range of blast pots

- Digital display of actual blasting time for individual blast outlets

- Allows you to determine productivity, production rates, assisting project costings, job estimates and scheduling maintenance for common wear items

- System available to run off pneumatic and electric deadman controls

- Triggered instantly by the deadman signal, so you get actual blasting hours

- Options available for single and multiple outlets.

-

- Newest generation abrasive metering valve with improved wear-life while maintaining fine metering control.

- Offers improved life and lower cost over previous generation Thompson valves.

- Pressure-hold design maintains pressure in the pot, even with deadman released. This can save up to 15% of abrasive when your projects involve a lot of start-stop blasting.

- Diaphragm-activated piston requires minimum of 75 psi control pressure

- Can be retrofitted to a blast pot with only 6" clearance

- Genuine Parts - Manufactured by Schmidt® / Axxiom Manufacturing

-

When Axxiom released the Thompson 2 valve, the benefits of Pressure-Hold technology were instantly upgraded by improved user experience over the Thompson I valve. Details as follows:

- Improved servicability:

- Body and cylinder are now 2 parts, providing easier removal of sleeve and plunger.

- Additional Seal protection:

- Has 3 separate seals (versus the original 1), reducing dust migration and improving durability.

- Multiple Sleeve choices:

- In addition to the original Tungsten Carbide and Urethane full-flow options, Axxiom has released additional options that help prevent over-consumption in various applications.

- Virtual Position Indicator:

- Simplifies setting of the media flow rate.

- Cleanout:

- Full 1" port directly under the inlet allows cleanout without removing the valve.

- Size info:

- Standard 1-¼” (32 mm) inlet thread

- 4 choices of MNPT piping for pusher-line connection

- 1", 1-¼", 1-½", and 2"

- Options: Make servicing the valve even more convenient with one of the following:

- Union-End Ball Valve - The UEBV allows removal of valve without emptying the pot.

- Tri-Clover Quick Connect - allows removal of valve without tools.

- Combination UEBV and Tri-Clover - combines the benefits of both options at a reduced cost.

Meter your abrasive efficiently and conveniently with the genuine Axxiom Thompson II valve!

- Improved servicability:

-

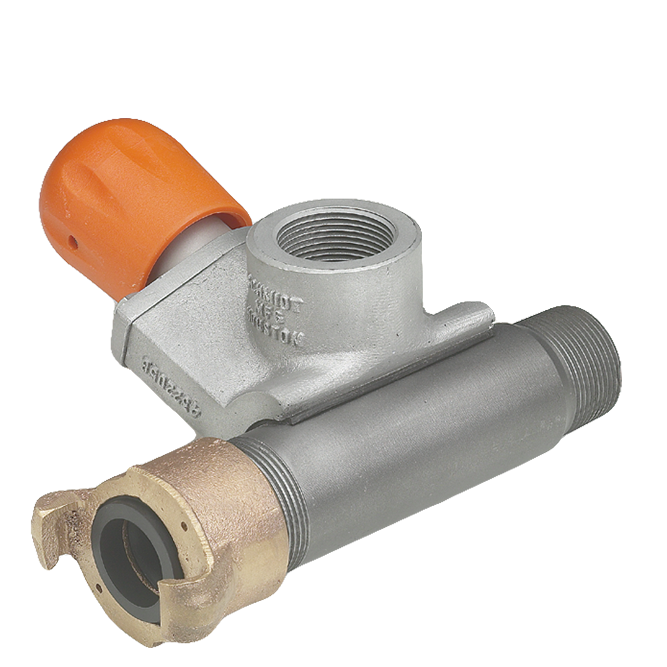

- Pressure-release deadman control valve i.e., blast machine depressurizes when the deadman handle is released.

- Used when an overhead hopper automatically feeds abrasive into a blast machine.

- Rugged stainless steel body, compact, isolated 2-bolt construction.

- Doubles blast machine refill cycle time.

- Virtual Position Indicator illustrates orifice size, giving the ability to set abrasive flow quickly and consistently.

- Set and forget – flow rates stay set where you put them.

- High wear, rugged plunger seal.

- Stainless steel body for long life.

- Improved urethane clean-out port enabling quick removal of obstructions while improving port and valve life.

- Fit a rebuild kit while the valve is still fitted to the blast machine.

- Sold individually.

- Genuine Products – Manufactured by Schmidt / Axxiom Manufacturing

-

Enhance your blasting efficiency with the Schmidt® MicroValve Abrasive Metering Valve. Designed for precise abrasive flow, this rugged valve ensures optimal sandblasting media use.

- The MicroValve™ changed the industry by providing accurate metering valve

- Most pressure-release Schmidt pots now use the newer MicroValve® 3

- Simple screw type metering through a low-wearing valve

- 1 ¼" (32 mm) thread abrasive inlet port

- Hardened steel threaded base nipple

- Sold Individually, Brass Coupling not included

- Genuine Products - Manufactured by Schmidt® / Axxiom Manufacturing

- The MicroValve™ changed the industry by providing accurate metering valve

-

The Thompson Valve II XL™ showcases Axxiom's continuous improvement process. Adding XL™ technology to the legendary Thompson valve, this premium valve lasts up to 10 times longer than all previous Thompson valves, due to its unique engineering.

- Withstands aggressive medias (like steel grit or aluminum oxide) and high-wear dusty abrasives.

- Will support up to a #12 (3/4") blast nozzle

- Upgraded components and internal wipers to keep the critical areas protected

- Most universal of the Axxiom XL™ series of valves - supports robotic, high-volume blasting

- Sold Individually

- Many choices of sizes and tungsten sleeve configurations, as follows:

- 1" base, std. sleeve. MPN: 2153-006

- 1.25" base, std. sleeve. MPN: 2153-007

- 1.5" base, std. sleeve. MPN: 2153-008

- 1.25" base, slotted sleeve. MPN: 2153-217

- 1.5" base, slotted sleeve. MPN: 2153-218

- 1.25" base, multi-port sleeve. MPN: 2153-437

- 1.5" base, multi-port sleeve. MPN: 2153-438

- (slotted and multi-port sleeves are designed to limit the maximum abrasive flow, saving abrasive when the valve is opened too far.)

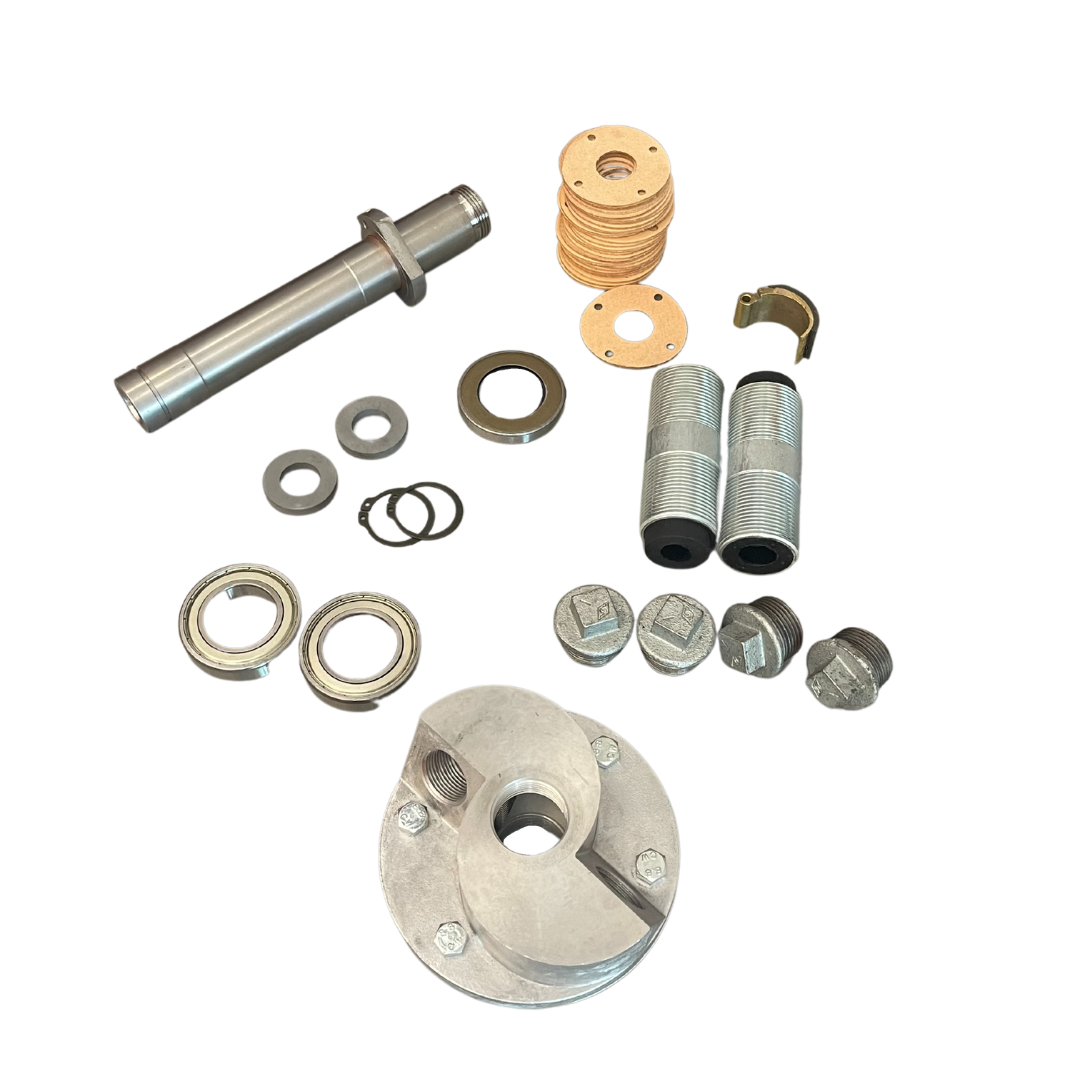

Explore our extensive range of blast equipment parts designed to enhance and maintain your blasting operations. From deadman control systems to high-pressure fittings, we provide everything you need to keep your equipment running smoothly and efficiently. Our selection includes durable components like hex pipe nipples, pop-up valves, and hose fittings, ensuring compatibility and high performance. Trust in our products to deliver reliability and safety across all your blasting projects.

My Account

My Account

Abrasive Metering Valves & Parts

Abrasive Metering Valves & Parts Air Control Valves & Related

Air Control Valves & Related Deadman / Control Systems

Deadman / Control Systems General Repair Parts for Blast Pots

General Repair Parts for Blast Pots Internal Pipe (ID) System Components

Internal Pipe (ID) System Components MistBlaster Specific Parts

MistBlaster Specific Parts Sponge Blast Equipment Parts

Sponge Blast Equipment Parts Vacuum Blaster Workheads, Parts & Related

Vacuum Blaster Workheads, Parts & Related VertiDrive Specific Parts

VertiDrive Specific Parts