Blast Equipment

Showing 16–30 of 91 results

-

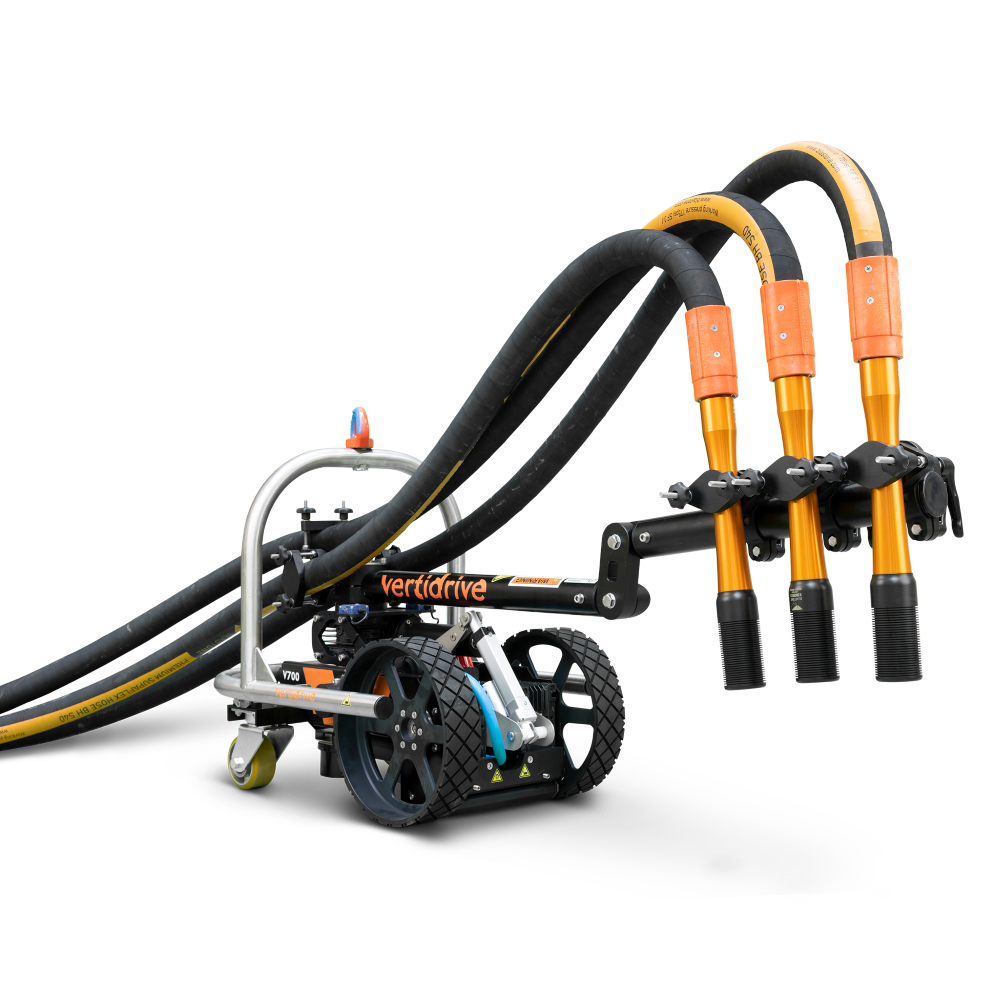

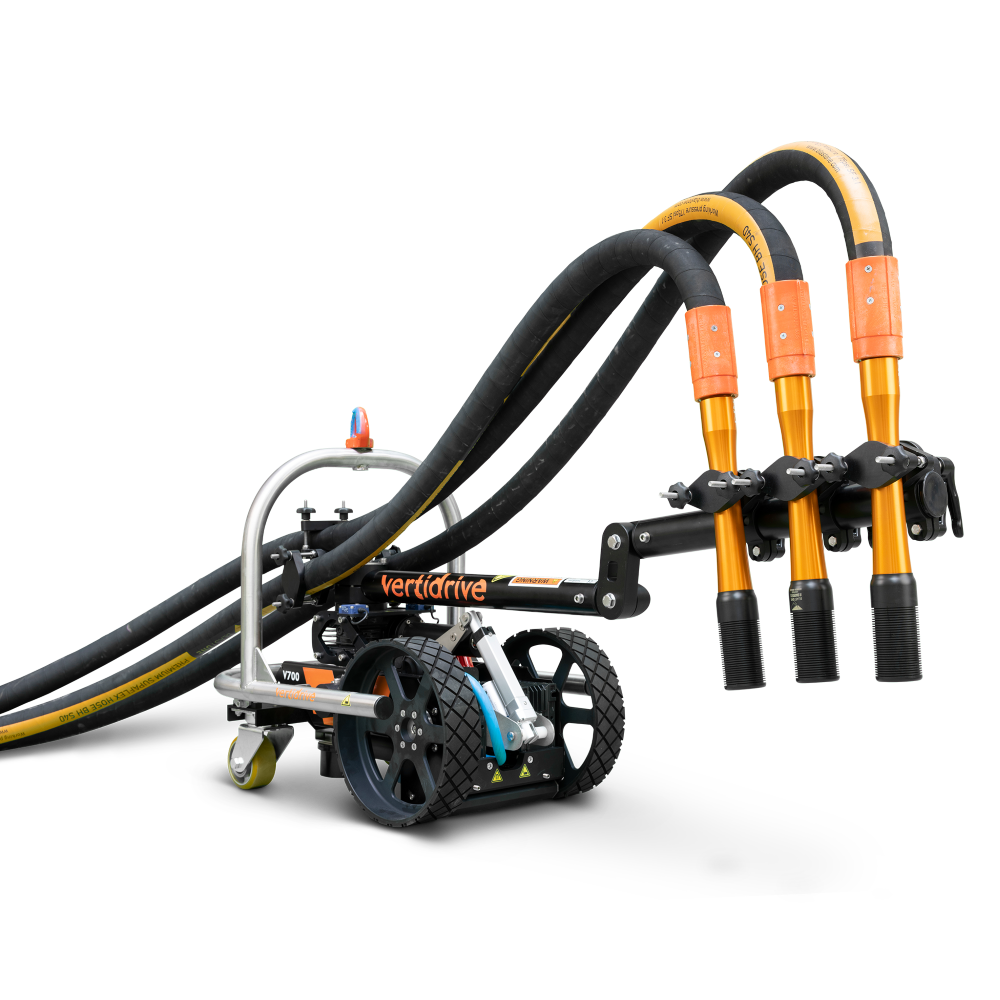

RUBVDV700BlastOne's VertiDrive V700 Blasting Robot represents the cutting edge in surface preparation technology, engineered to revolutionize large-scale blasting projects. This next-generation robotic system, exclusively developed by BlastOne, sets a new industry standard for performance, efficiency, and safety. RENT or PURCHASE this surface preparation work-horse! The next-generation V700 VertiDrive. Boosting performance and profits on large blasting projects. Purchase pricing is typically between $125,000 and $204,000, depending on configuration. BlastOne can provide on-site training and ongoing support to ensure maximum productivity from Day 1. Schedule a call with our SMEs to calculate and expected ROI for your next project.

- Faster Production. Now holds up to 3 nozzles and each nozzle is up to 30% faster than the best hand blasting. Highest productivity of any robotic blasting system!

- Cleaner Surface. Provides consistent blasting quality by adjustment of equipment speed to the specific surface needs.

- Safer. Remote control operation removes the operator from harms way.

- Capable. Boosted magnetic performance allows standard operation on carbon steel surfaces that are horizontal, vertical, and now even upside-down!

- Versatile. The V700 can be configured in 3 ways:

- Abrasive Blasting. Can blast either wet or dry.

- Ultra High Pressure (UHP) coating removal.

- Power Wash surface cleaning.

- Reduced Cost-of-Ownership. The VertiDrive V700 has the lowest maintenance cost of any blasting robot.

- Looking for more information? Click here to read more…

RUBVDV700BlastOne's VertiDrive V700 Blasting Robot represents the cutting edge in surface preparation technology, engineered to revolutionize large-scale blasting projects. This next-generation robotic system, exclusively developed by BlastOne, sets a new industry standard for performance, efficiency, and safety. RENT or PURCHASE this surface preparation work-horse! The next-generation V700 VertiDrive. Boosting performance and profits on large blasting projects. Purchase pricing is typically between $125,000 and $204,000, depending on configuration. BlastOne can provide on-site training and ongoing support to ensure maximum productivity from Day 1. Schedule a call with our SMEs to calculate and expected ROI for your next project.- Faster Production. Now holds up to 3 nozzles and each nozzle is up to 30% faster than the best hand blasting. Highest productivity of any robotic blasting system!

- Cleaner Surface. Provides consistent blasting quality by adjustment of equipment speed to the specific surface needs.

- Safer. Remote control operation removes the operator from harms way.

- Capable. Boosted magnetic performance allows standard operation on carbon steel surfaces that are horizontal, vertical, and now even upside-down!

- Versatile. The V700 can be configured in 3 ways:

- Abrasive Blasting. Can blast either wet or dry.

- Ultra High Pressure (UHP) coating removal.

- Power Wash surface cleaning.

- Reduced Cost-of-Ownership. The VertiDrive V700 has the lowest maintenance cost of any blasting robot.

- Looking for more information? Click here to read more…

-

MB60160Boost profits and reduce frustration by converting your EcoQuip® blasting rig to MistBlaster® technology.

- Boost profits by:

- Increased production speed

- Reduced wasted abrasive and rust inhibitor

- Less water usage, reduced cleanup time

- Winning more projects because dry blasting is easy too!

- Reduce frustrations by:

- No need to drain the tank at end of day

- Allows adjustment of water / abrasive ratio

MB60160Boost profits and reduce frustration by converting your EcoQuip® blasting rig to MistBlaster® technology.- Boost profits by:

- Increased production speed

- Reduced wasted abrasive and rust inhibitor

- Less water usage, reduced cleanup time

- Winning more projects because dry blasting is easy too!

- Reduce frustrations by:

- No need to drain the tank at end of day

- Allows adjustment of water / abrasive ratio

- Boost profits by:

-

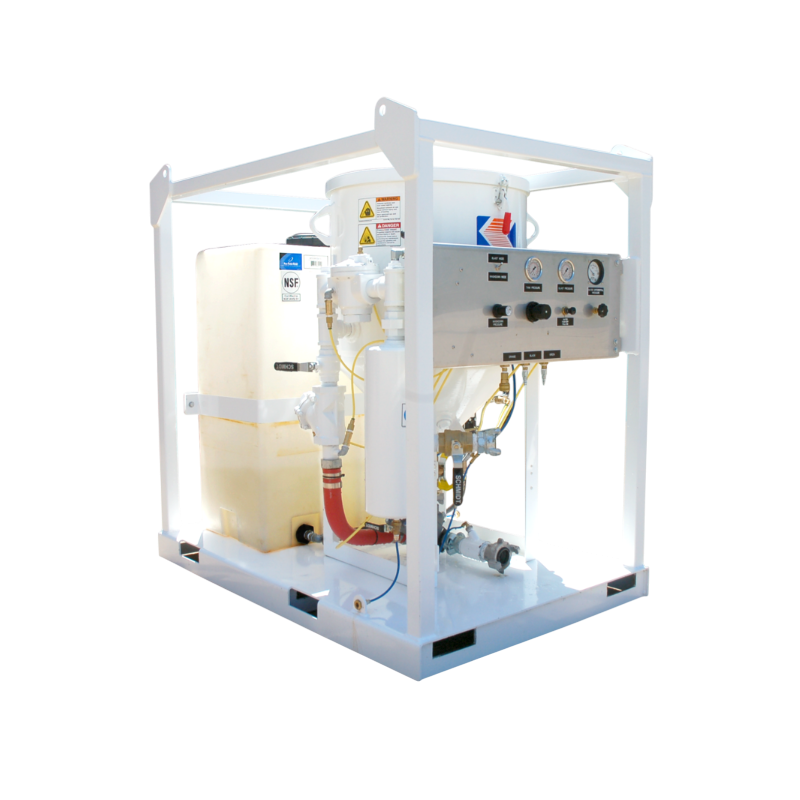

The Schmidt® Bulk AmphiBlast™ is a high-capacity wet/dry blasting system (aka Dustless Mega Blaster or Dustless Bulk Pot) that features proven Schmidt controls and innovative moisture injection technology for precise air, abrasive, and water flow control. Available in multiple configurations with up to four independently controlled blast outlets, this system delivers maximum productivity, efficiency, and versatility. Key Features:

- Operate up to four nozzles simultaneously with individual mode settings

- Advanced abrasive metering technology with choice of either the Thompson II or the TeraValve

- Switch between wet blast, dry blast, Softwash™, and blowoff with ease

- Available in 45 cf, 120 cf, and 160 cf capacities

- HALOK® Closure Safety System for enhanced operator protection

- Ergo-Ladder® with anti-slip twisted rungs for safe access

- Mounting options include:

- Shipping Legs - use when mounting on existing customer equipment

- Custom Steel Skid w/forklift pockets

- Yard Trailer

- Highway Trailer

-

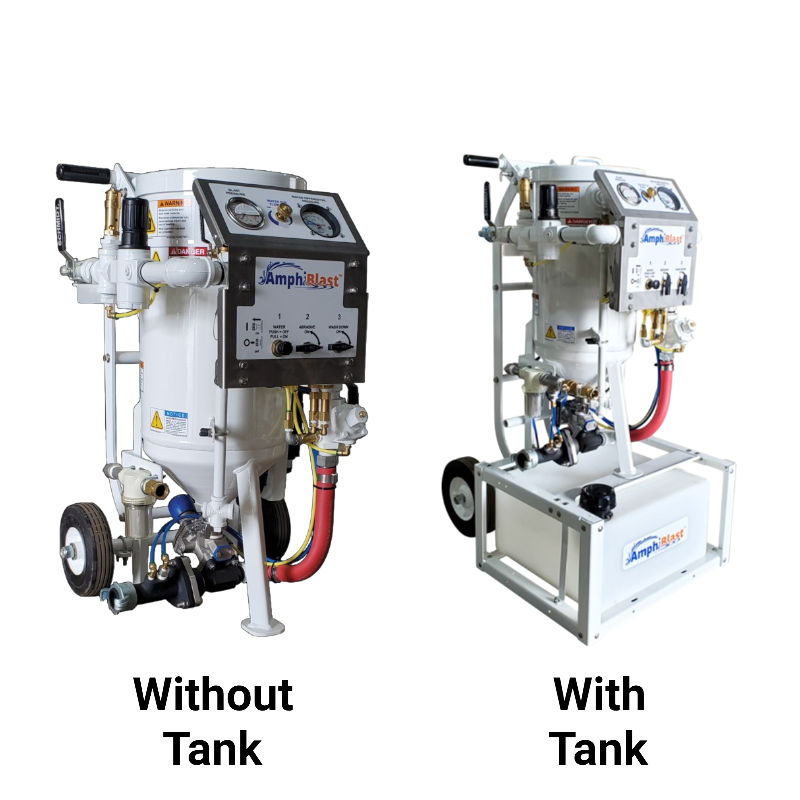

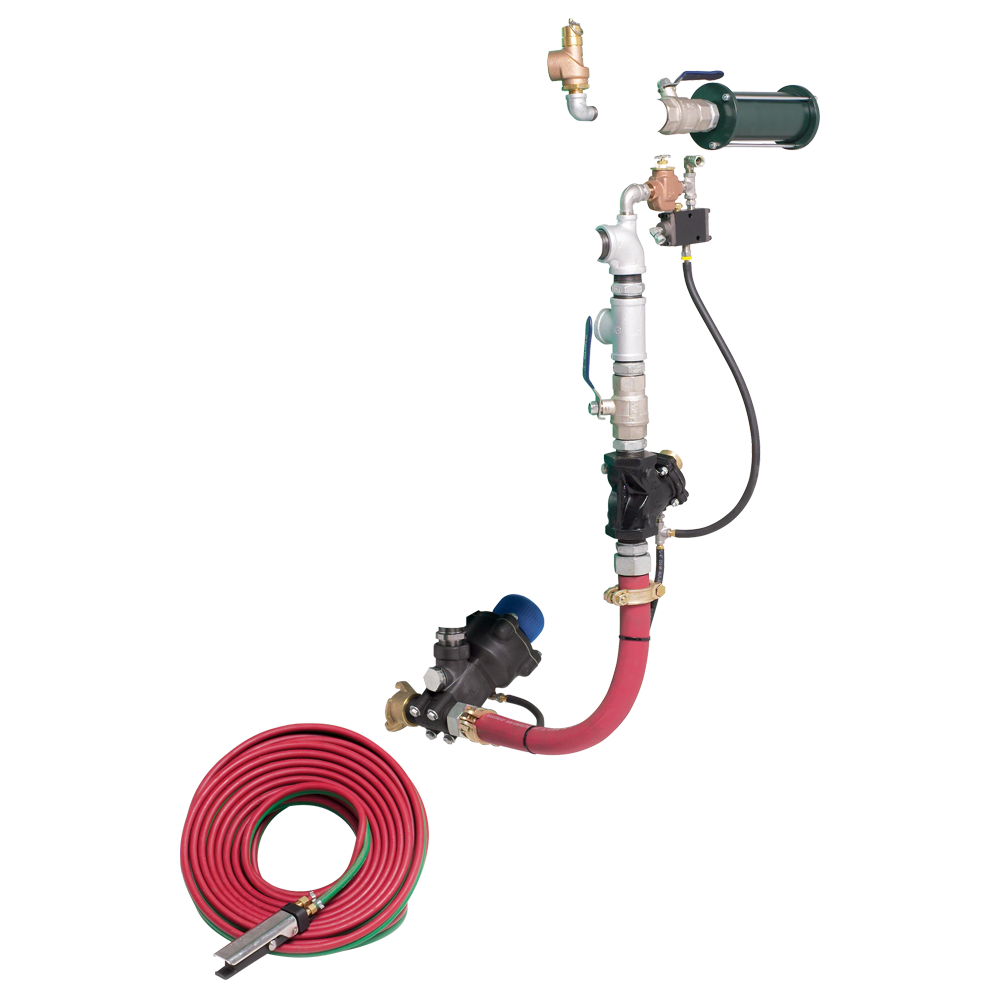

The Schmidt® AmphiBlast™ is a versatile, dual-purpose abrasive blasting system designed for efficient wet and dry blasting. Featuring a patent-pending water injection system and Schmidt® Thompson® Valve II, it offers precise control of air, abrasive, and water flows for maximum productivity and minimal material waste. Available in single and dual outlet configurations, all with fork-pocket skid mounts. Key Features:

- Switch between wet blast, dry blast, Softwash™, and blowoff effortlessly.

- Precise water injection for optimal blasting performance and minimal water use

- Supports a wide range of abrasives (coarse and fine)

- High and low-pressure blasting capabilities

- Set and Forget mode switching for consistent performance

- Improved lid construction and quieter blowdown system

- Size Options:

- 1-Outlet, 4.5 cu. ft. Blast Pot | 80-Gallon Water Tank

- 2-Outlet, 6.5 cu. ft. Blast Pot | 165-Gallon Water Tank

- Controls Choices:

- Pneumatic w/Compact BAABS G3 Trigger Deadman

- 12v Electric w/Compact BAABS G3 Trigger Deadman

- Abrasive Cut-Off (ACO) available on 2-outlet 12v Electric

- (The BAABS is the innovative ergonomic system by Schmidt that pairs perfectly with the G3 deadman)

-

The Clemco Wetblast FLEX™ System is a versatile wet and dry blasting solution, designed for maximum flexibility and productivity. Whether you're blasting in dust-sensitive urban areas or open environments requiring dry blasting, the FLEX system adapts to any job, helping you stay compliant, efficient, and profitable. Key Features:

- Switch between wet and dry blasting with ease

- High-performance water injection system for optimal dust suppression

- Precise water adjustment controls for customizable blasting

- 120-gallon water storage tank with pump included for flexible water sourcing

- Easy-to-use controls for quick setup and operation

- Available in Base Unit and Flex Package configurations

-

The Clemco Pro-Series Big Clem Abrasive Bulk Blasters are engineered for maximum productivity, faster refills, and superior safety. With 175-PSI rated pressure vessels, the fastest refill cycles, and the versatile GritWizard abrasive metering valve, these bulk blasters are designed to handle all common media and streamline operations for efficient, high-volume blasting.

Key Features:

- 175-PSI rated pressure vessels – Highest in the industry

- 20% faster refill cycle – Maximizes uptime and productivity

- GritWizard metering valve – Handles all common media with precision control

- Optimized plumbing for maximum pressure delivery

- Improved Super Sack System – Faster, safer abrasive refills

- Pop-up valves – Industry-standard safety for pressure sealing

- Enhanced safety features – Noise-reducing outlet muffler, ergonomic controls, and secure lifting points

-

The Schmidt AmphiBlast™ Mini 1.5 cu. ft. Blast Pot is the most compact and portable wet/dry blasting system in the AmphiBlast family. Designed for high productivity and efficiency, this lightweight unit allows for precise control over air, abrasive, and water flow, minimizing waste and maximizing performance. Available in electric and pneumatic modes, with optional onboard water tank. Key Features:

- Seamlessly switch between wet blast, dry blast, blowoff, and Softwash™

- Minimal water use (less than 1 pint / ½ liter per minute)

- Compact design fits through a 24” doorway (even with onboard tank)

- Schmidt Tera Valve™ XL metering valve for precise abrasive control

- Electric water pump provides high-flow washdown capabilities

- Wide pressure range (10–150 psi) for either delicate or aggressive blasting

-

Get your new abrasive blasting pot set up right with this BlastOne Hose & Nozzle Bundle Package. Built for contractors, each package includes air and blast hoses, the latest Infinity nozzle technology, and all the essentials you need—all with the trusted BlastOne quality. Save money versus buying a la carte and pick the option that fits your job best.

- Bundle Group 1: Includes options with 50' blast hose & standard setup for shorter hose length and/or smaller compressor capacity

- Bundle Group 2: Includes options with 100' blast hose & extended setup for larger jobs and/or higher air flow

- Includes the latest BlastOne Infinity nozzle in your choice of orifice size

- Save time & money with these all-in-one contractor-ready kits

- BlastOne quality—built to perform in the field

-

The Clemco Power Gun H2O Portable Suction Wetblaster offers a lightweight, portable solution for wet abrasive blasting. Ideal for spot work and small projects, it is used on projects requiring dust mitigation. Its design eliminates the need for a blast pot, making it perfect for confined spaces and quick setups.

Key Features:

- Portable and lightweight design for easy maneuverability

- Operates without the need for a traditional blast pot

- Ideal for spot work and small-scale projects

- Wet blasting capability reduces dust for safer operation

- Quick setup with minimal equipment requirements

- Suitable for use in confined or hard-to-reach areas

-

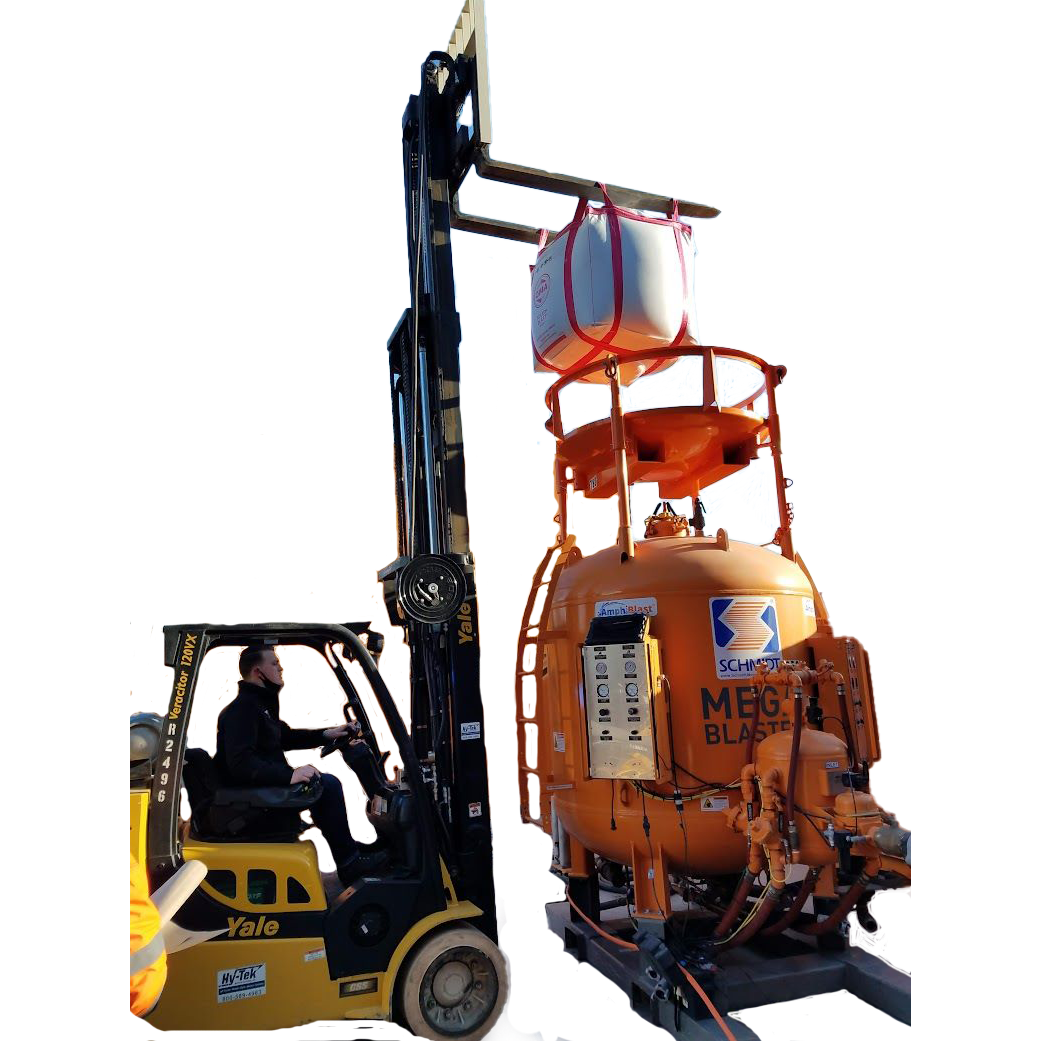

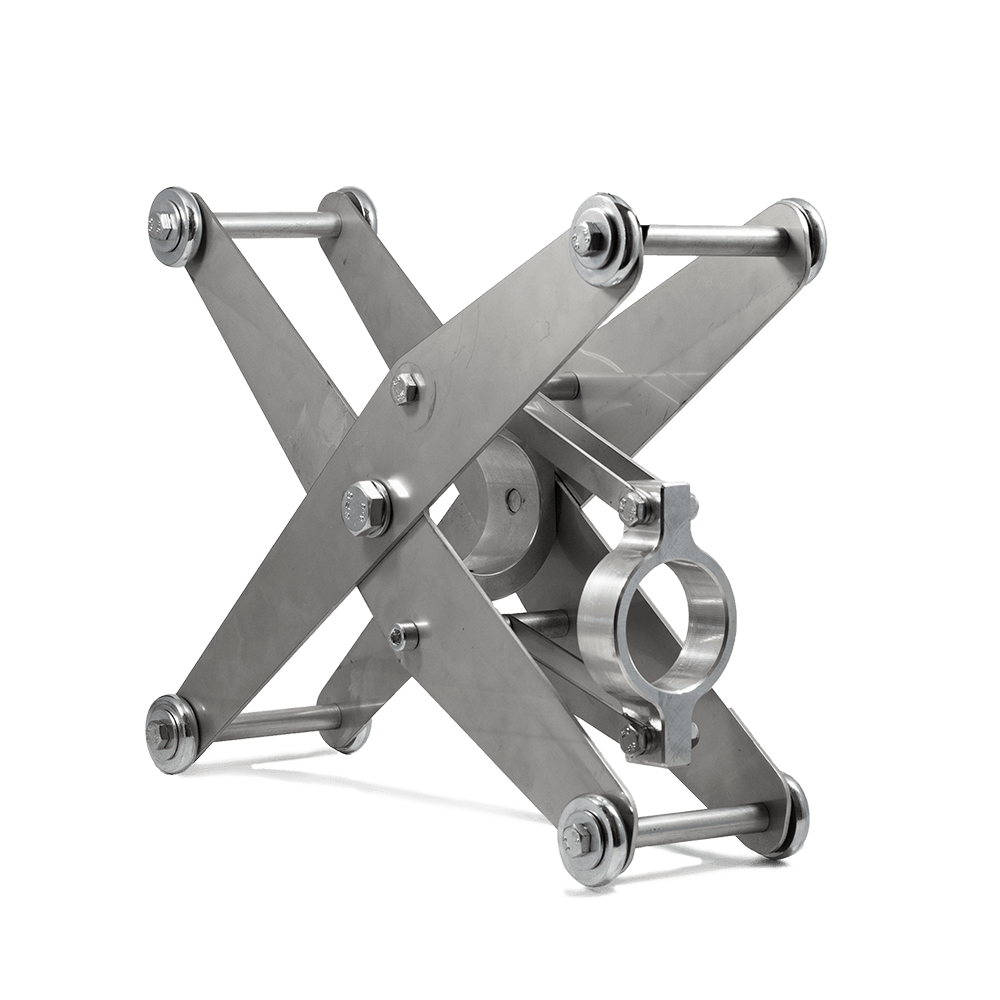

Upfit your Axxiom / Schmidt Mega Bulk Blaster with a Bulk Bag Rack to assist with safe, efficient abrasive loading. Designed to handle heavy-duty use on job sites, this optional rack improves loading safety and minimizes operator strain with forklift-friendly features and adjustable legs. Two versions available:

- Two Square models, for 120CF or 160CF vessels

- One Round model, which fits both 120CF and 160CF units

- Forklift pockets for easier handling

- Adjustable legs ensure stable, versatile setup

- Optional accessory designed to reduce operator risk and simplify abrasive bag handling

- MPNs: 8400-018-73, 8400-018-84, 8400-018-85

-

SBMGI

- High quality, acoustically insulated steel sandwich panel construction

- Ideal for consistent blasting production (1 operator, 20-40 hrs/week)

- Various material handling options: product carts, forklift loading, manual handling

- Partial or Full-floor abrasive recovery system

- Airwash abrasive cleaner for grit recycling with vibrating screen for trash removal

- Reverse pulse cartridge dust collector

- Typical size ranging from:

- 10’ W x 10’ H x 10’ L (small)

- 22’ W x 22’ H x 100’ L (large)

SBMGI- High quality, acoustically insulated steel sandwich panel construction

- Ideal for consistent blasting production (1 operator, 20-40 hrs/week)

- Various material handling options: product carts, forklift loading, manual handling

- Partial or Full-floor abrasive recovery system

- Airwash abrasive cleaner for grit recycling with vibrating screen for trash removal

- Reverse pulse cartridge dust collector

- Typical size ranging from:

- 10’ W x 10’ H x 10’ L (small)

- 22’ W x 22’ H x 100’ L (large)

-

SBMGSHeavy Duty Blast Room can be designed for use with any steel or heavy machinery manufacturers, refinishing facilities, for oil and gas components, or in job shops. The "General Purpose Custom Engineered Blast Rooms and Facilities" (SKU: SBMGS) are heavy-duty, long-term sandblasting solutions. Designed for diverse industrial needs, these rooms feature robust steel panels, advanced abrasive recovery systems, and extensive customizability. Ideal for consistent operations seeking a controlled blasting environment.SBMGSHeavy Duty Blast Room can be designed for use with any steel or heavy machinery manufacturers, refinishing facilities, for oil and gas components, or in job shops. The "General Purpose Custom Engineered Blast Rooms and Facilities" (SKU: SBMGS) are heavy-duty, long-term sandblasting solutions. Designed for diverse industrial needs, these rooms feature robust steel panels, advanced abrasive recovery systems, and extensive customizability. Ideal for consistent operations seeking a controlled blasting environment.

-

SBMGT

- Permanent or temporary mounting systems

- Ideal for setting up temporary blasting/painting facilities

- Supplied in modular kit for simple, quick installation (under a week)

- Fully relocatable — easy to install and dismantle

- 100% Waterproof design

- Wind rating as per local requirements

- No concrete foundation necessary

- Compatible with optional abrasive recovery and dust collection equipment

SBMGT- Permanent or temporary mounting systems

- Ideal for setting up temporary blasting/painting facilities

- Supplied in modular kit for simple, quick installation (under a week)

- Fully relocatable — easy to install and dismantle

- 100% Waterproof design

- Wind rating as per local requirements

- No concrete foundation necessary

- Compatible with optional abrasive recovery and dust collection equipment

-

- Robots made by Blastman Robotics specifically for Blastroom applications

- Available as 4-Axis, 7-Axis or 8-Axis.

- Available as Wall Mount or Gantry Mount

- Optional Man cabin for manual blasting which can come mounted on the blasting arm, or as a separate cabin

- 20+ years of installation and robotic experience

- Read here for more pictures of Blastman Blasting Robots

Why Choose BlastOne’s Blast Equipment?

BlastOne’s blast equipment stands out for its reliability and innovation. Features like ergonomic designs, efficient media usage, and compatibility with various abrasives make our equipment a preferred choice. Our products are backed by expert support and comprehensive training resources, ensuring you get the most out of your investment.

Stay ahead in your projects with equipment that meets stringent industry standards and adapts to evolving needs. Trust BlastOne for solutions that enhance productivity and deliver consistent results.

My Account

My Account

Small Blast Pots

Small Blast Pots Contractor Blast Pots

Contractor Blast Pots Specialty Blast Pots

Specialty Blast Pots MistBlaster Wet / Dry Pots

MistBlaster Wet / Dry Pots Mega Bulk Blasters

Mega Bulk Blasters Robotic / Vertidrive Equipment

Robotic / Vertidrive Equipment Track Blasters

Track Blasters Internal Pipe (ID) Systems

Internal Pipe (ID) Systems Blast Machine Accessories

Blast Machine Accessories