Abrasive Metering Valves & Parts

Showing 31–45 of 125 results

-

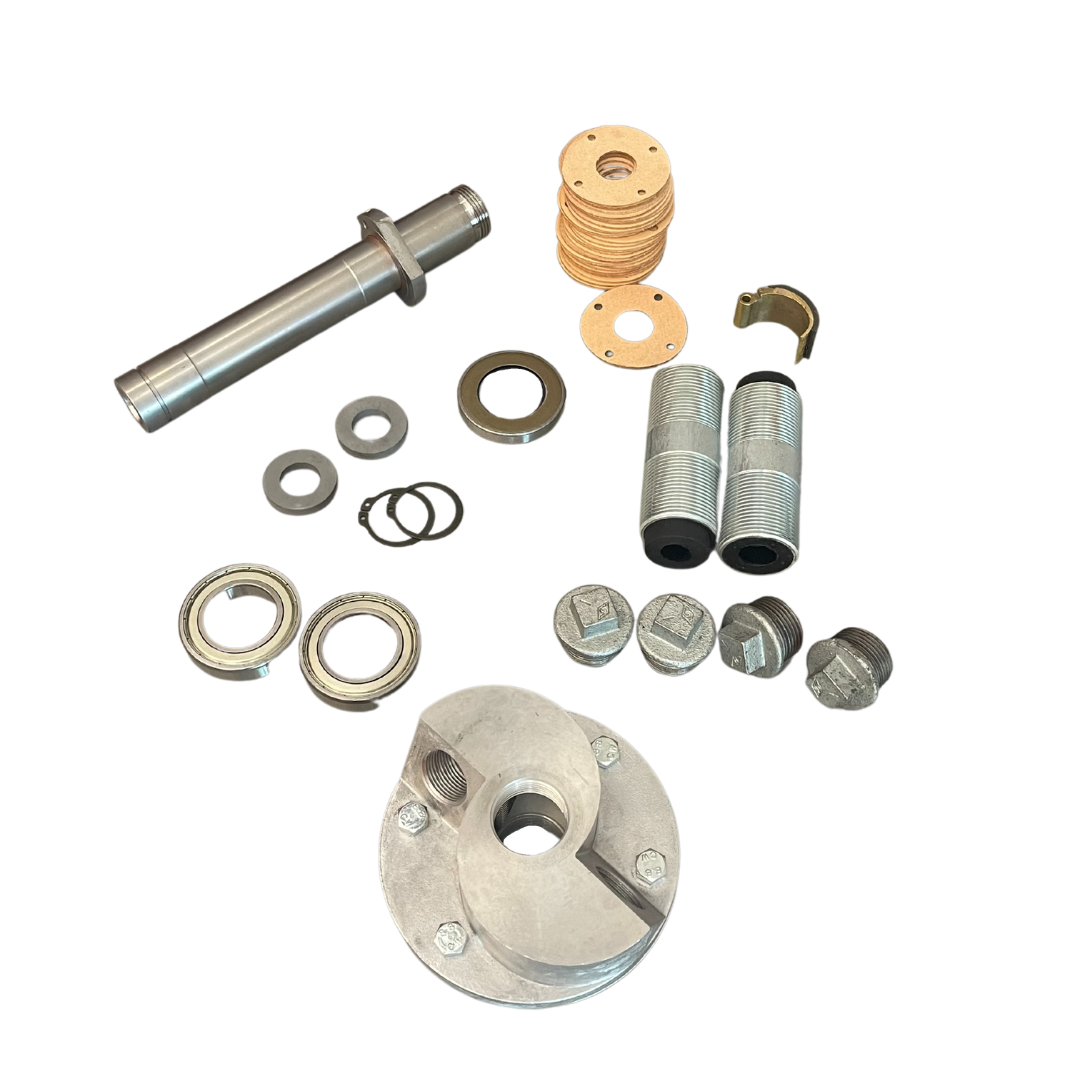

GV212710099

- Repair Kit for MicroValve

- Replacement Repair Kit for MicroValve III

- Schmidt abrasive blasting equipment/ Axxiom Manufacturing part number 2127-100-99

- Complete Rebuild Kit for MicroValve 2 Schmidt / Axxiom part # 2127-100-99 Includes: GV214950006, GV212700005, GV701100506, GV212700012, GV212700015, and GV212710008

GV212710099- Repair Kit for MicroValve

- Replacement Repair Kit for MicroValve III

- Schmidt abrasive blasting equipment/ Axxiom Manufacturing part number 2127-100-99

- Complete Rebuild Kit for MicroValve 2 Schmidt / Axxiom part # 2127-100-99 Includes: GV214950006, GV212700005, GV701100506, GV212700012, GV212700015, and GV212710008

-

GV215300098

- OEM Replacement Seals Kit for Thompson® Valve II XL™

- Replacement Seals / O-Rings only

- Schmidt® / Axxiom part # 2153-000-98

GV215300098- OEM Replacement Seals Kit for Thompson® Valve II XL™

- Replacement Seals / O-Rings only

- Schmidt® / Axxiom part # 2153-000-98

-

BlastOne has the repair parts you need to maintain your Schmidt® Thompson II metering valves. Replacement sleeves are available in several variants as follows:

- Urethane - recommended for steel shot/grit

- Tungsten Carbide - recommended longer life sleeve for applications other than steel shot/grit

- Tungsten Carbide Keyslot - specialized port shaped like a keyhole, prevents overconsumption of abrasive even if the valve is wide open.

- Multi-Port Sleeve - offers multiple port sizes, designed to prevent overconsumption of abrasive in various mesh sizes

-

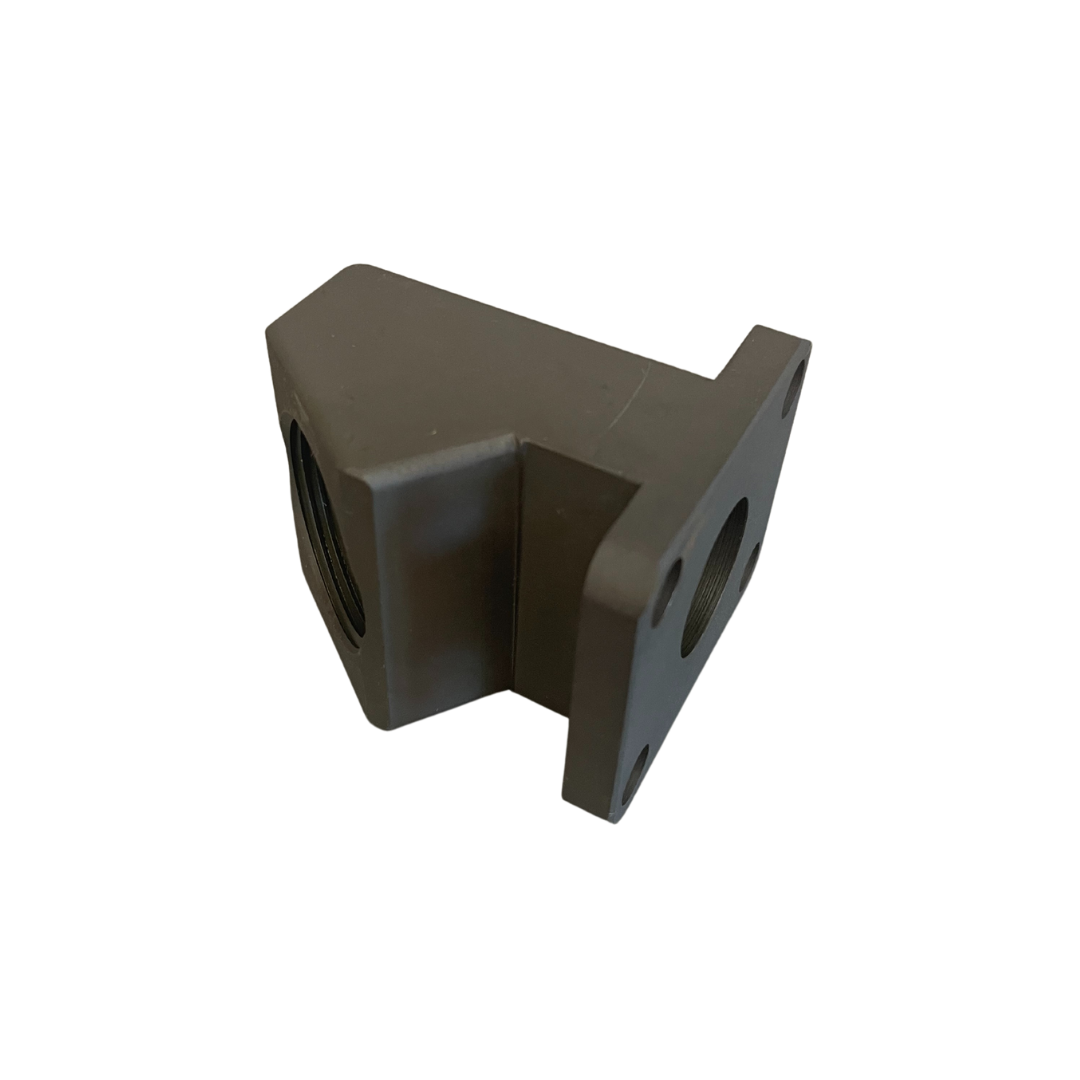

GV215230715

- Replacement direct down base for the 2152-009 Schmidt Jumbo Thompson II Abrasive Metering Valve

- MPN 2152-307-15

GV215230715- Replacement direct down base for the 2152-009 Schmidt Jumbo Thompson II Abrasive Metering Valve

- MPN 2152-307-15

-

- Newest generation abrasive metering valve with improved wear-life while maintaining fine metering control.

- Offers improved life and lower cost over previous generation Thompson valves.

- Pressure-hold design maintains pressure in the pot, even with deadman released. This can save up to 15% of abrasive when your projects involve a lot of start-stop blasting.

- Diaphragm-activated piston requires minimum of 75 psi control pressure

- Can be retrofitted to a blast pot with only 6" clearance

- Genuine Parts - Manufactured by Schmidt® / Axxiom Manufacturing

-

When Axxiom released the Thompson 2 valve, the benefits of Pressure-Hold technology were instantly upgraded by improved user experience over the Thompson I valve. Details as follows:

- Improved servicability:

- Body and cylinder are now 2 parts, providing easier removal of sleeve and plunger.

- Additional Seal protection:

- Has 3 separate seals (versus the original 1), reducing dust migration and improving durability.

- Multiple Sleeve choices:

- In addition to the original Tungsten Carbide and Urethane full-flow options, Axxiom has released additional options that help prevent over-consumption in various applications.

- Virtual Position Indicator:

- Simplifies setting of the media flow rate.

- Cleanout:

- Full 1" port directly under the inlet allows cleanout without removing the valve.

- Size info:

- Standard 1-¼” (32 mm) inlet thread

- 4 choices of MNPT piping for pusher-line connection

- 1", 1-¼", 1-½", and 2"

- Options: Make servicing the valve even more convenient with one of the following:

- Union-End Ball Valve - The UEBV allows removal of valve without emptying the pot.

- Tri-Clover Quick Connect - allows removal of valve without tools.

- Combination UEBV and Tri-Clover - combines the benefits of both options at a reduced cost.

Meter your abrasive efficiently and conveniently with the genuine Axxiom Thompson II valve!

- Improved servicability:

-

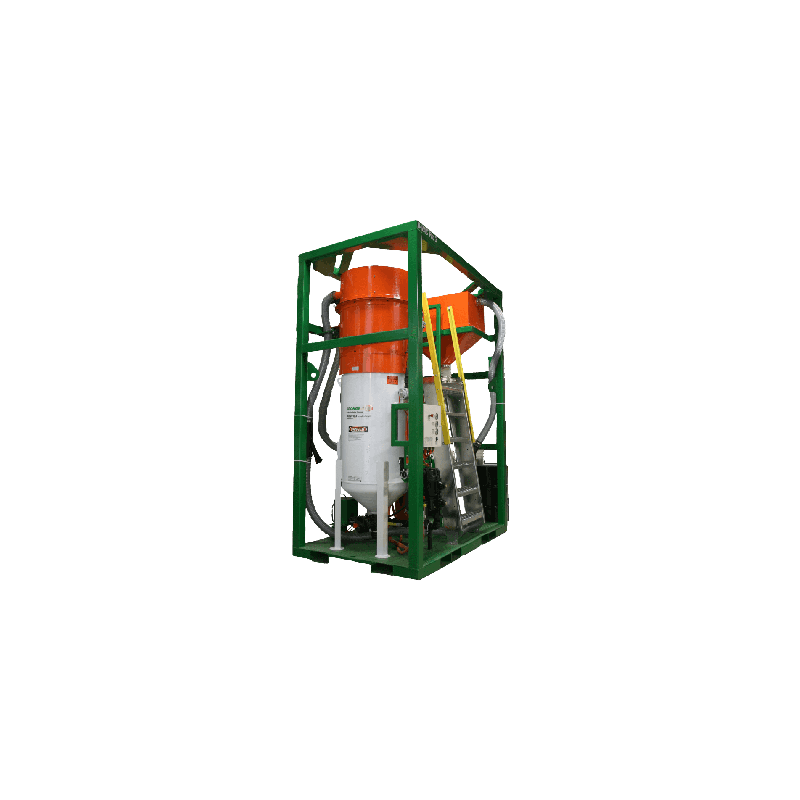

- Pressure-release deadman control valve i.e., blast machine depressurizes when the deadman handle is released.

- Used when an overhead hopper automatically feeds abrasive into a blast machine.

- Rugged stainless steel body, compact, isolated 2-bolt construction.

- Doubles blast machine refill cycle time.

- Virtual Position Indicator illustrates orifice size, giving the ability to set abrasive flow quickly and consistently.

- Set and forget – flow rates stay set where you put them.

- High wear, rugged plunger seal.

- Stainless steel body for long life.

- Improved urethane clean-out port enabling quick removal of obstructions while improving port and valve life.

- Fit a rebuild kit while the valve is still fitted to the blast machine.

- Sold individually.

- Genuine Products – Manufactured by Schmidt / Axxiom Manufacturing

-

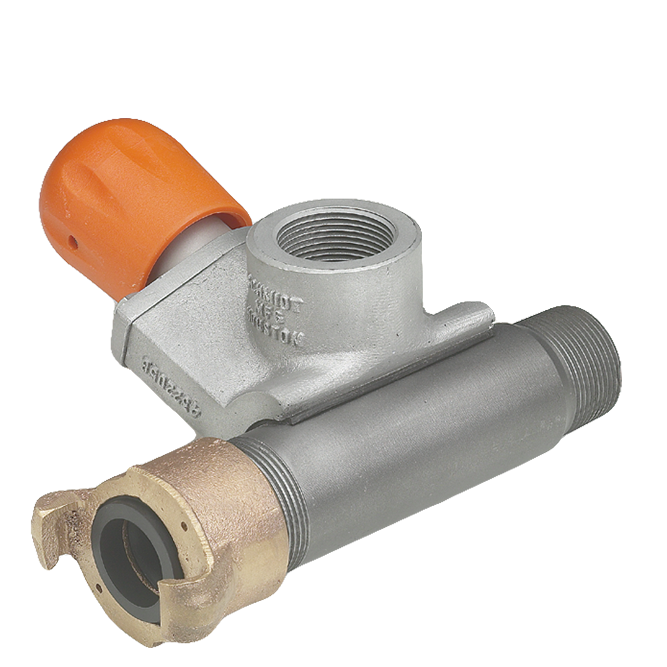

Enhance your blasting efficiency with the Schmidt® MicroValve Abrasive Metering Valve. Designed for precise abrasive flow, this rugged valve ensures optimal sandblasting media use.

- The MicroValve™ changed the industry by providing accurate metering valve

- Most pressure-release Schmidt pots now use the newer MicroValve® 3

- Simple screw type metering through a low-wearing valve

- 1 ¼" (32 mm) thread abrasive inlet port

- Hardened steel threaded base nipple

- Sold Individually, Brass Coupling not included

- Genuine Products - Manufactured by Schmidt® / Axxiom Manufacturing

- The MicroValve™ changed the industry by providing accurate metering valve

-

The Thompson Valve II XL™ showcases Axxiom's continuous improvement process. Adding XL™ technology to the legendary Thompson valve, this premium valve lasts up to 10 times longer than all previous Thompson valves, due to its unique engineering.

- Withstands aggressive medias (like steel grit or aluminum oxide) and high-wear dusty abrasives.

- Will support up to a #12 (3/4") blast nozzle

- Upgraded components and internal wipers to keep the critical areas protected

- Most universal of the Axxiom XL™ series of valves - supports robotic, high-volume blasting

- Sold Individually

- Many choices of sizes and tungsten sleeve configurations, as follows:

- 1" base, std. sleeve. MPN: 2153-006

- 1.25" base, std. sleeve. MPN: 2153-007

- 1.5" base, std. sleeve. MPN: 2153-008

- 1.25" base, slotted sleeve. MPN: 2153-217

- 1.5" base, slotted sleeve. MPN: 2153-218

- 1.25" base, multi-port sleeve. MPN: 2153-437

- 1.5" base, multi-port sleeve. MPN: 2153-438

- (slotted and multi-port sleeves are designed to limit the maximum abrasive flow, saving abrasive when the valve is opened too far.)

-

The Thompson I Valve was invented by Bob Schmidt and was instrumental in causing the popularity of pressure hold technology.

- Pressure-hold systems retain the pressure in the blast pot until the deadman handle is depressed. This reduces abrasive and energy waste.

- The Thompson I offers fine control for abrasive metering

- It comes in 3 nipple size configurations:

- 1 ¼” (32 mm) x 1 ¼” (32 mm)

- 1 ½" (38 mm) x 1 ½" (38 mm)

- 2" (50 mm) x 2" (50 mm)

- Threaded-plunger metering design with air actuated operation

- Fits most sand blast hoppers, blast pots or abrasive blasting machines

- Genuine Parts - Manufactured by Schmidt® / Axxiom Manufacturing

-

GV02427

- The Flat Sand Valve is the classic Clemco abrasive metering valve used for sandblasting for nearly 100 years.

- Used in most new Classic blast machine pots

- The FSV is simple and economical and provides abrasive metering control for expendable mineral abrasives and slags (not recommended for steel grit or aluminum oxide).

- The valve uses a simple lever and keyslot to control the flow of abrasive from the blast pot into the blast hose

- It is good practice to keep a complete spare valve on hand to use when needed, repairing the worn valve at a convenient later time.

- Genuine Clemco Part Number 02427

GV02427- The Flat Sand Valve is the classic Clemco abrasive metering valve used for sandblasting for nearly 100 years.

- Used in most new Classic blast machine pots

- The FSV is simple and economical and provides abrasive metering control for expendable mineral abrasives and slags (not recommended for steel grit or aluminum oxide).

- The valve uses a simple lever and keyslot to control the flow of abrasive from the blast pot into the blast hose

- It is good practice to keep a complete spare valve on hand to use when needed, repairing the worn valve at a convenient later time.

- Genuine Clemco Part Number 02427

-

The Flat Sand Valve is legacy metering technology, where the metering is performed by sliding a lever to open and close the abrasive port. It is simple in design and relatively inexpensive, but has a few limitations. Details as follows:

- Slide-plate metering design, controlled by lever

- 1 1/4" (32 mm) ports

- Features side cleanout-inspection port

- Available with or without outlet nipple and Y-piece (Optional rubber lined nipple is available to extend nipple life.)

- The major limitations are:

- Not recommended for use with metallic abrasives

- The slide plate/lever design does not provide effective fine metering control. Typically this results in over consumption of media. For low-volume blasting using inexpensive media, this may not be an issue.

-

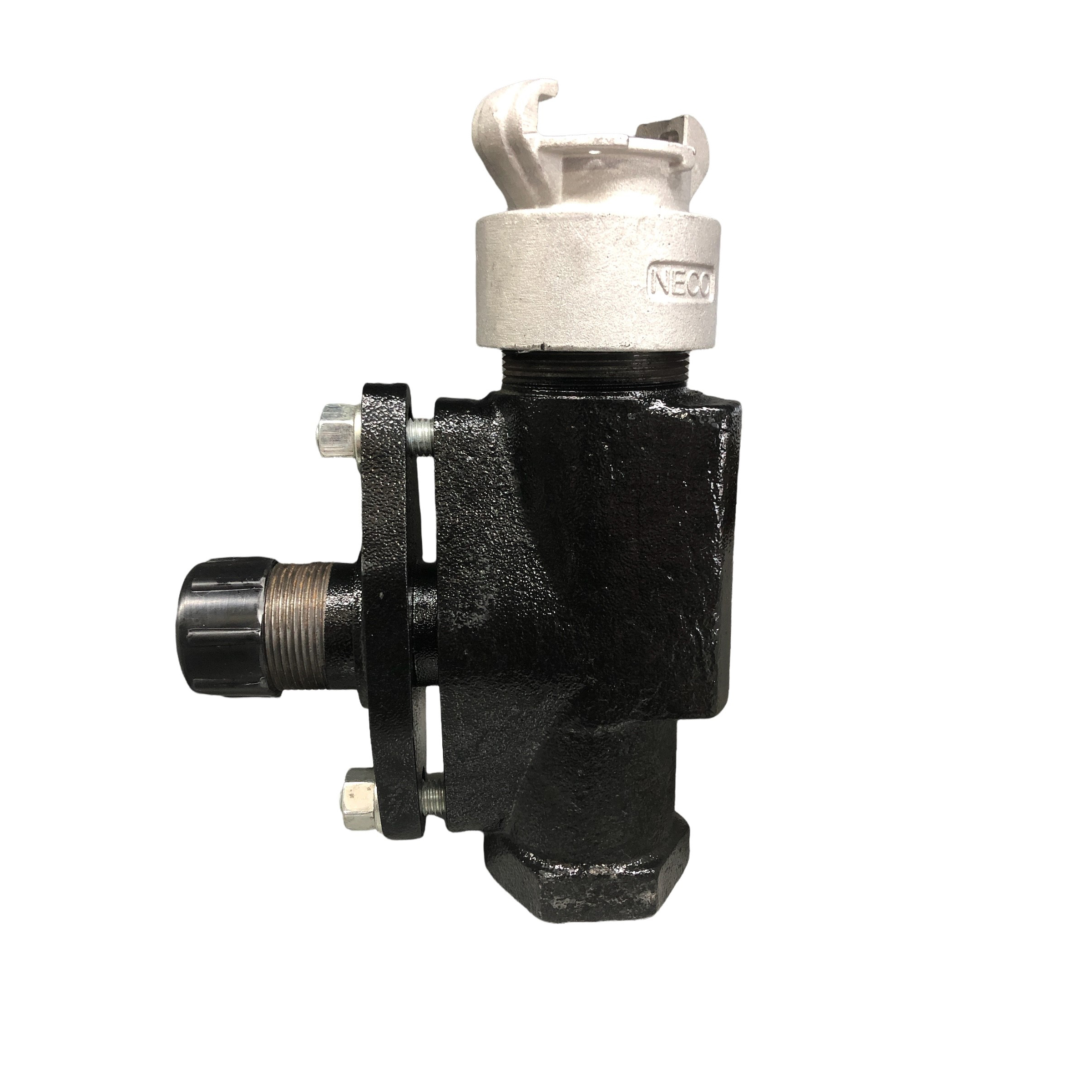

GVDNV100

- HFSTC3 blast coupling included

- Designed for use with coarse metallic abrasives

- Heavy cast iron construction

- Not recommended for use with fine abrasives

- 1 1/2" NPT female thread air connection

- Recommended upgrade: MicroValve 3

GVDNV100- HFSTC3 blast coupling included

- Designed for use with coarse metallic abrasives

- Heavy cast iron construction

- Not recommended for use with fine abrasives

- 1 1/2" NPT female thread air connection

- Recommended upgrade: MicroValve 3

-

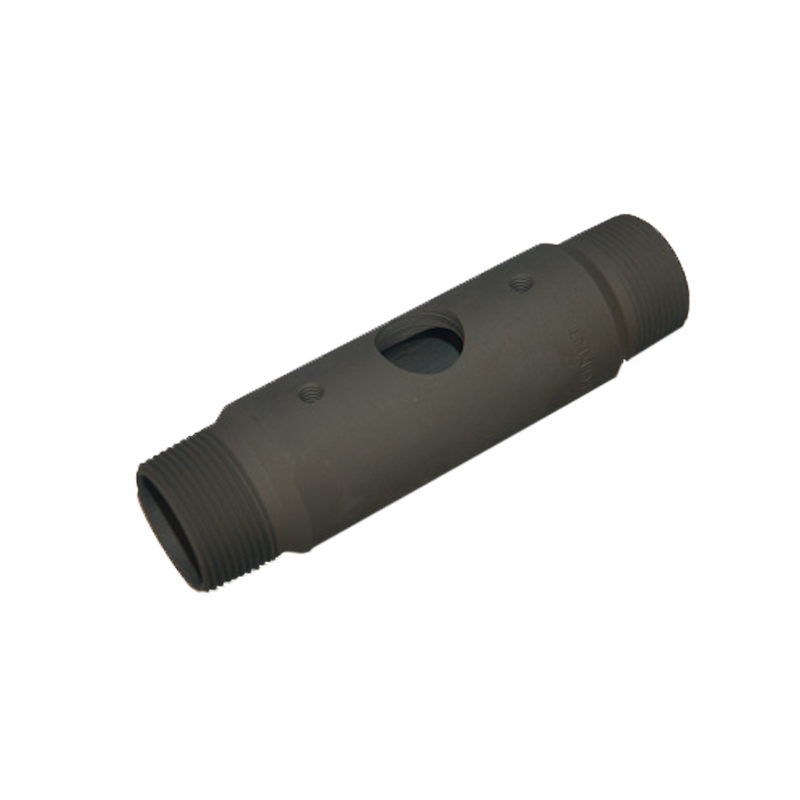

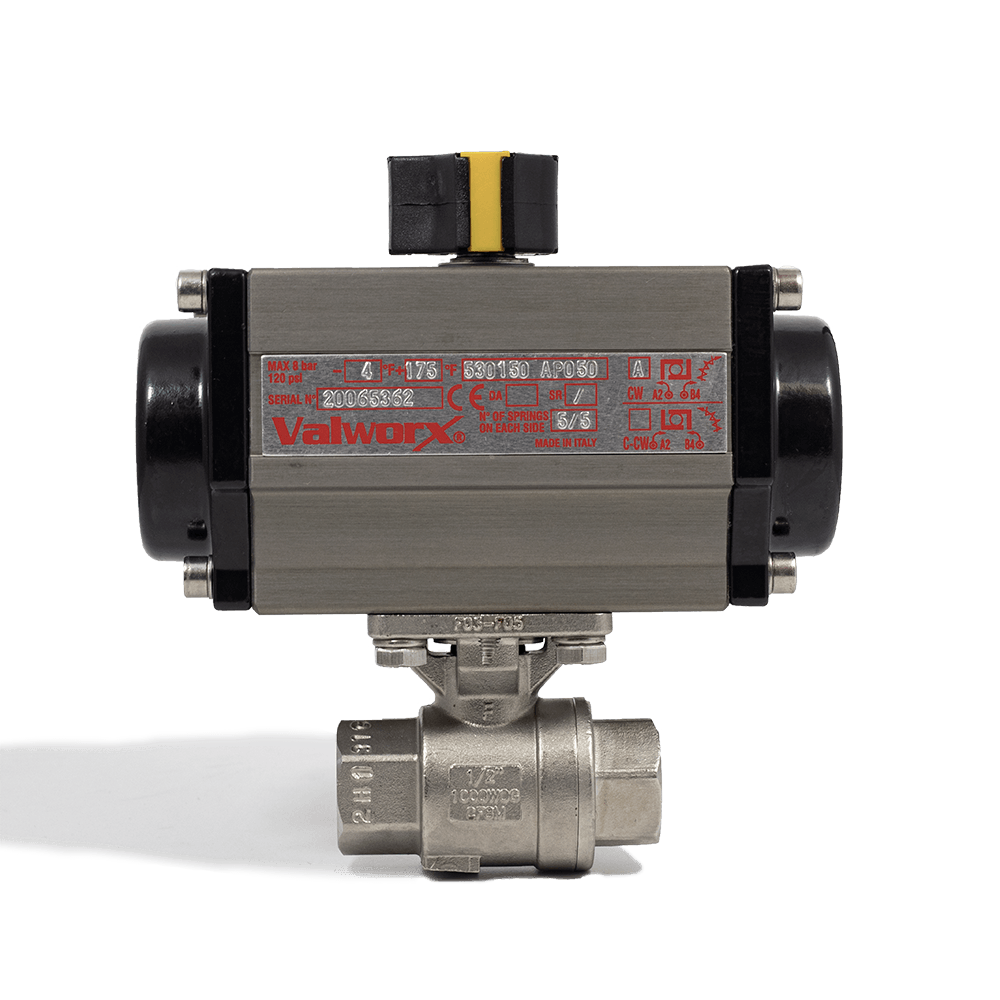

GV2410320

- Suits most blast pots and valves (any with 1-1/4" NPT Thread)

- Locate between the metering valve and the bottom of the pot to reduce maintenance time on the metering valve.

- Allows easy removal of metering valve from pot

- Can be used independently, or in conjunction with a Union End Ball valve. To order this combination as a unit, use part number GV2410320SPBV (saves cost).

GV2410320- Suits most blast pots and valves (any with 1-1/4" NPT Thread)

- Locate between the metering valve and the bottom of the pot to reduce maintenance time on the metering valve.

- Allows easy removal of metering valve from pot

- Can be used independently, or in conjunction with a Union End Ball valve. To order this combination as a unit, use part number GV2410320SPBV (saves cost).

-

GV2410320SP

- Suits most blast pots and valves (any with 1-1/4" NPT thread)

- Locate between the metering valve and the bottom of the pot to reduce maintenance on the metering valve

- Allows easy removal of metering valve from pot

- Can be used independently, or in conjunction with a Union End Ball Valve. To order this combination as a unit, use part number GV2410320SPBV (saves cost).

- Alternate version to Tri-clover assembly without spring-loaded hinge

GV2410320SP- Suits most blast pots and valves (any with 1-1/4" NPT thread)

- Locate between the metering valve and the bottom of the pot to reduce maintenance on the metering valve

- Allows easy removal of metering valve from pot

- Can be used independently, or in conjunction with a Union End Ball Valve. To order this combination as a unit, use part number GV2410320SPBV (saves cost).

- Alternate version to Tri-clover assembly without spring-loaded hinge

My Account

My Account

Abrasive Metering Valves

Abrasive Metering Valves Abrasive Metering Valve Parts

Abrasive Metering Valve Parts Air Control Valves & Related

Air Control Valves & Related Deadman / Control Systems

Deadman / Control Systems General Repair Parts for Blast Pots

General Repair Parts for Blast Pots Internal Pipe (ID) System Components

Internal Pipe (ID) System Components MistBlaster Specific Parts

MistBlaster Specific Parts Sponge Blast Equipment Parts

Sponge Blast Equipment Parts Vacuum Blaster Workheads, Parts & Related

Vacuum Blaster Workheads, Parts & Related VertiDrive Specific Parts

VertiDrive Specific Parts