Blast Equipment

Showing 61–75 of 91 results

-

Portable Sponge-Jet® feed units (aka Sponge Pots) come in a variety of configurations to suit almost every application. From small, value-based units to fully featured machines, sponge feed units are designed for the ultimate in low-dust abrasive blasting. Seven configurations are available, as follows:

- RASP Xtreme™ 3:

- Highly portable & fits thru a 24 inch manway

- Holds 1 bag of new sponge media (5-7 minutes)

- Includes pressure relief valve (PRV) & integrated wheels

- Great for spot work

- 127 lb. empty weight

- 100-HP Feed Unit™:

- Great balance between size, cost & blast time

- Fits through a 30" doorway

- Holds 3 bags of new sponge media

- Includes PRV, secondary moisture separator & wheels

- Great for preservation work

- 480 lb. empty weight

- CG Series (Contractor Grade Series):

- 2 sizes available:

- 170-CG - holds 5 bags of new sponge media

- 470-CG - holds 13 bags of new sponge media

- Value series - ideal where few features are required

- Includes fork pockets

- Great for yard work

- 600 lb. / 1142 lb. empty weights for 170-CG / 470-CG

- 2 sizes available:

- SJ Series (Feed Unit Series):

- 2 sizes available:

- 170-SJ - holds 5 bags of new sponge media

- 170-EX - similar to 170-SJ, but ATEX 2 rated for potentially flammable environments

- 470-SJ - holds 13 bags of new sponge media

- Fully featured, includes:

- Pressure relief valve

- Secondary moisture separator

- Muffler

- Frame w/casters and lifting lugs

- Centralized controls

- Great for field work

- 900 lb / 1000 lb / 1515 lb empty weights respectively

- 2 sizes available:

- RASP Xtreme™ 3:

-

BMPIPSYSL375ACT

-

HTIBIX06EBFOR RENTAL OR PURCHASE

-

-

- FREE Shipping

- 30 Day Money-Back Guarantee | Free Returns

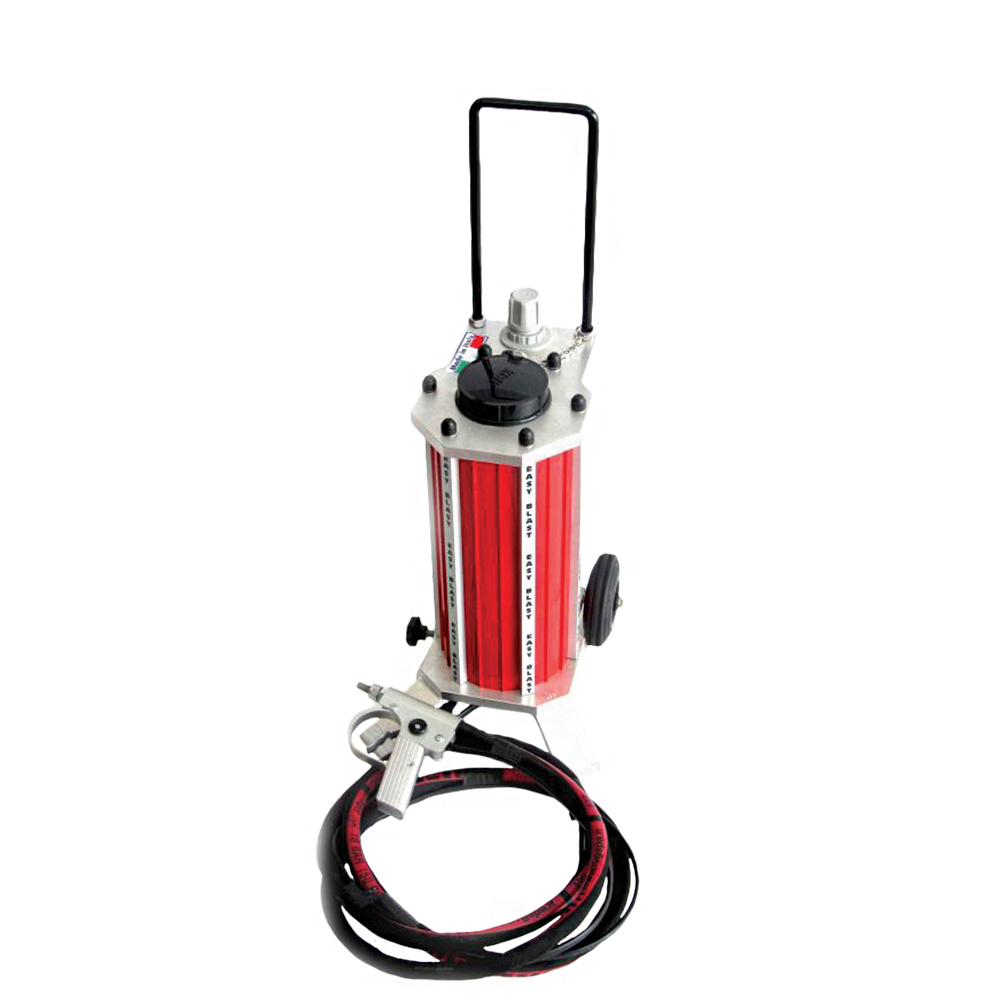

- The IBIX 6 Blaster is a portable abrasive blasting system.

- Very light - Empty Weight is only 27lbs

- Ideal for touch-up and maintenance work.

- It's portability makes blasting in difficult access areas possible.

- Sold as a Kit with a 25' hose and application gun 1/8" nozzle.

- Genuine Parts - Manufactured by IBIX

-

HTIBIX06EBFOR RENTAL OR PURCHASE-

-

- FREE Shipping

- 30 Day Money-Back Guarantee | Free Returns

- The IBIX 6 Blaster is a portable abrasive blasting system.

- Very light - Empty Weight is only 27lbs

- Ideal for touch-up and maintenance work.

- It's portability makes blasting in difficult access areas possible.

- Sold as a Kit with a 25' hose and application gun 1/8" nozzle.

- Genuine Parts - Manufactured by IBIX

-

-

-

HTIBIX25The IBIX 25 Portable Blaster is a compact, lightweight aluminum blasting system built for both wet and dry abrasive blasting. Designed for mobility and precision, it’s perfect for a wide range of surface preparation applications like rust removal, graffiti cleanup, and historical restoration.

- Wet and dry blasting in one compact unit

- Adjustable blasting pressure from 3 to 110 psi

- 6.6-gallon (25-liter) blast media tank capacity

- Lightweight aluminum build—only 83 lbs. (empty)

- Includes 30 ft. blast hose and IBIX-Pro Gun with #2.5 (5.5 mm) nozzle

- Compatible with soda, garnet, walnut shell, crushed glass, and more

- MPN: IBIX25

HTIBIX25The IBIX 25 Portable Blaster is a compact, lightweight aluminum blasting system built for both wet and dry abrasive blasting. Designed for mobility and precision, it’s perfect for a wide range of surface preparation applications like rust removal, graffiti cleanup, and historical restoration.- Wet and dry blasting in one compact unit

- Adjustable blasting pressure from 3 to 110 psi

- 6.6-gallon (25-liter) blast media tank capacity

- Lightweight aluminum build—only 83 lbs. (empty)

- Includes 30 ft. blast hose and IBIX-Pro Gun with #2.5 (5.5 mm) nozzle

- Compatible with soda, garnet, walnut shell, crushed glass, and more

- MPN: IBIX25

-

BMS1602TVH1600

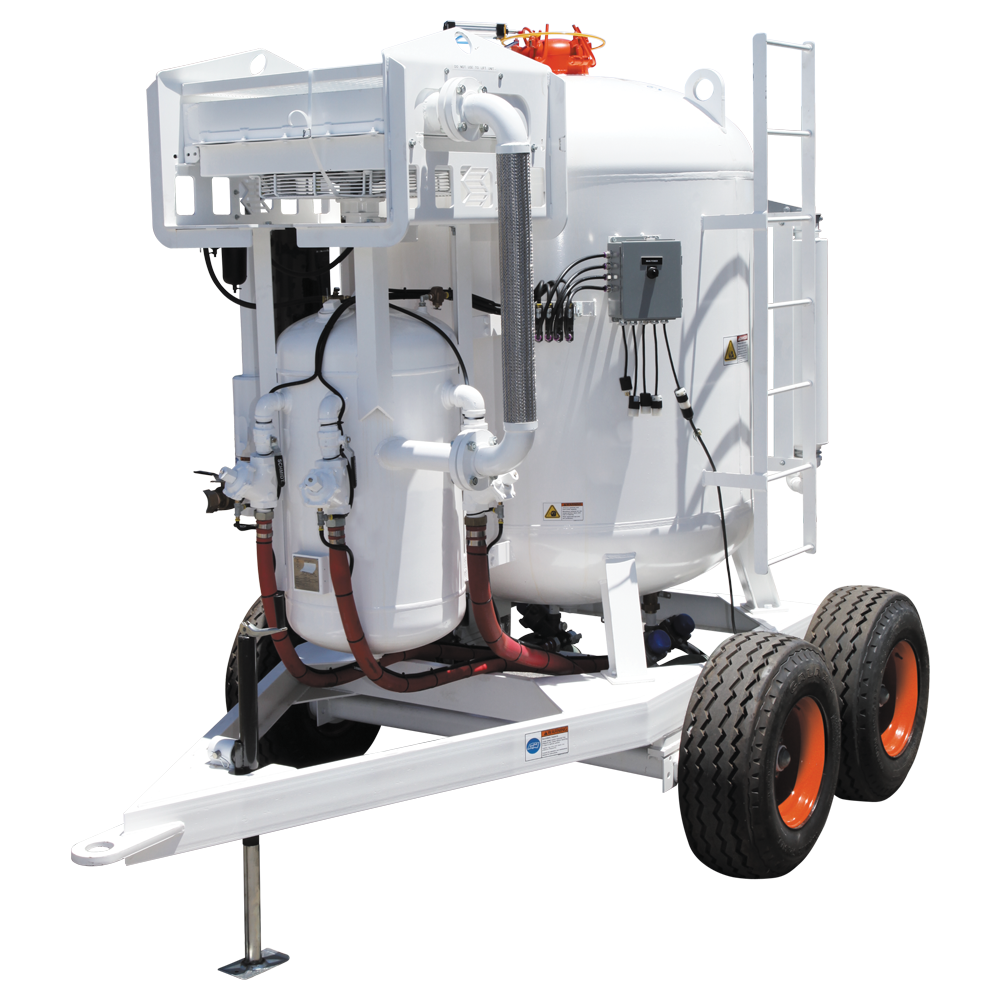

The Schmidt® Hybrid Bulk Blaster combines a high-capacity bulk blast machine with a built-in AirPrep™ air dryer, eliminating the need for a separate air dryer system. This integrated system saves space, reduces setup time, and keeps your air supply clean and moisture-free for consistent blasting performance.

- Integrated AirPrep™ air dryer—no separate dryer required. Every blast project needs a dryer - this integrated system saves time and money vs. using separate dryers.

- Multiple outlets, fitted with choice of Thompson® II valves or TeraValves

- Compact footprint reduces setup space

- Available in skid, yard trailer, or highway trailer mounts

- Same customization options as other Schmidt bulk blasters, including bulk bag loading racks, blasting time clocks, and more

Version pictured: SKU: BMS1602TVH1600 | (2) Thompson II valves | 160 cu. ft. | 1600 cfm deliquescent dryer

As each system is built-to-order, contact us with your specific equipment configuration requirements for a prompt quote.

BMS1602TVH1600The Schmidt® Hybrid Bulk Blaster combines a high-capacity bulk blast machine with a built-in AirPrep™ air dryer, eliminating the need for a separate air dryer system. This integrated system saves space, reduces setup time, and keeps your air supply clean and moisture-free for consistent blasting performance.

- Integrated AirPrep™ air dryer—no separate dryer required. Every blast project needs a dryer - this integrated system saves time and money vs. using separate dryers.

- Multiple outlets, fitted with choice of Thompson® II valves or TeraValves

- Compact footprint reduces setup space

- Available in skid, yard trailer, or highway trailer mounts

- Same customization options as other Schmidt bulk blasters, including bulk bag loading racks, blasting time clocks, and more

Version pictured: SKU: BMS1602TVH1600 | (2) Thompson II valves | 160 cu. ft. | 1600 cfm deliquescent dryer

As each system is built-to-order, contact us with your specific equipment configuration requirements for a prompt quote.

-

The latest innovation in deadman safety technology from Axxiom is the BAABS (Blasting Accessories and Assist Bracket System). Intended to be the safest deadman on the market, it mechanically prevents inadvertent activation. The Schmidt BAABS deadman is such a leap forward in safety technology that Axxiom provides them as standard equipment with most new blast pot or valve retrofit purchases.*

All BAABS use the Axxiom G3 trigger deadman configurable as either electric or pneumatic.

All BAABS units are capable of being fitted with the BAABS blast light for improved vision in dim or dusty environments. (Note: When the light is used with the Subcompact BAABS, there is not room for the thrust brace.)

*The standard configuration provided with new equipment is the Compact size. See Product Description tab for all size options.

-

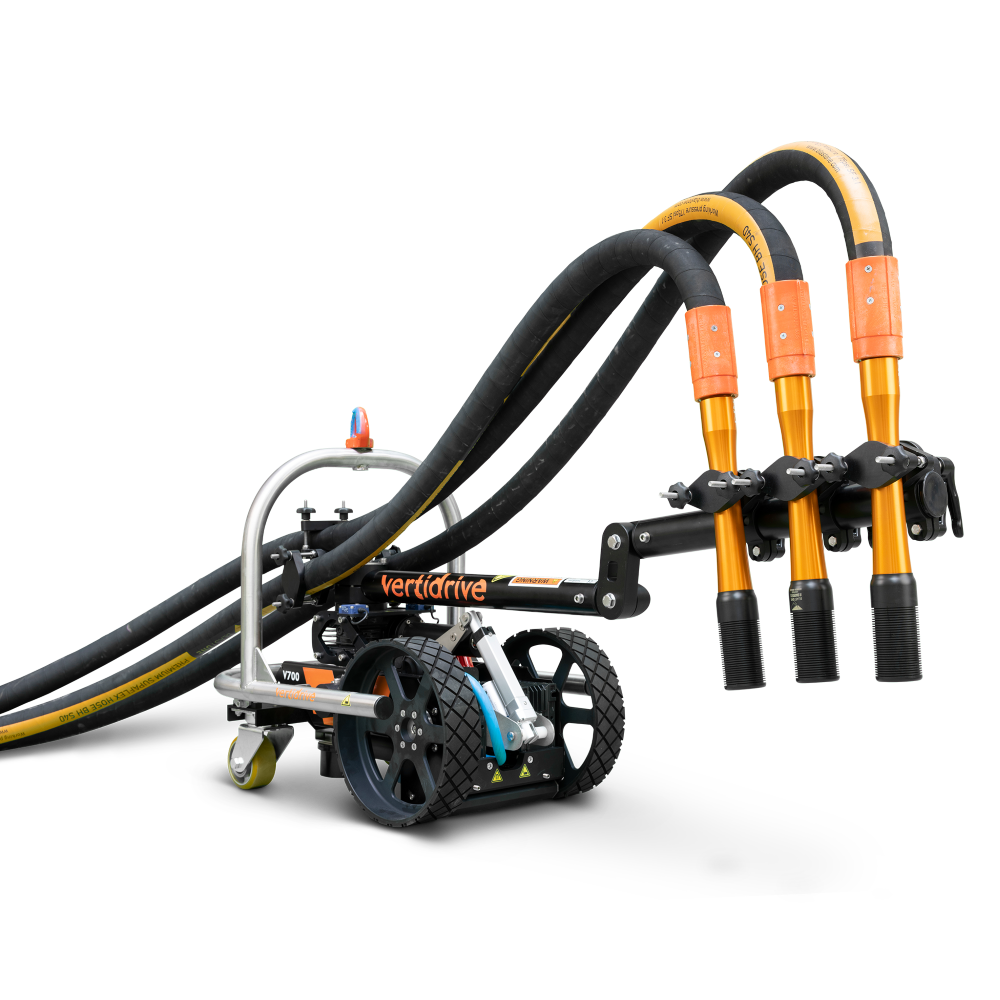

RUBVDM71BlastOne's VertiDrive M7 Blasting Robot is an innovative surface preparation powerhouse, engineered to revolutionize large-scale blasting projects. This advanced robotic system, developed exclusively by BlastOne, sets a new benchmark for efficiency, consistency, and safety in industrial surface treatment. RENT or PURCHASE this surface preparation work-horse! The original M7 VertiDrive. Bringing improved production to large blasting projects.

- Faster Production. Holds 2 nozzles simultaneously and each nozzle is up to 30% faster than the best hand blasting.

- Cleaner Surface. Provides consistent blasting quality by adjusting equipment speed to the specific surface needs.

- Safer. Remote control operation removes the operator from harms way.

- Capable. Blast both horizontal and vertical surfaces with ease.

- Versatile. The M7 can be configured in 3 ways:

- Abrasive Blasting. Can blast either wet or dry.

- Power Wash surface cleaning

- Ultra High Pressure (UHP) coating removal.

RUBVDM71BlastOne's VertiDrive M7 Blasting Robot is an innovative surface preparation powerhouse, engineered to revolutionize large-scale blasting projects. This advanced robotic system, developed exclusively by BlastOne, sets a new benchmark for efficiency, consistency, and safety in industrial surface treatment. RENT or PURCHASE this surface preparation work-horse! The original M7 VertiDrive. Bringing improved production to large blasting projects.- Faster Production. Holds 2 nozzles simultaneously and each nozzle is up to 30% faster than the best hand blasting.

- Cleaner Surface. Provides consistent blasting quality by adjusting equipment speed to the specific surface needs.

- Safer. Remote control operation removes the operator from harms way.

- Capable. Blast both horizontal and vertical surfaces with ease.

- Versatile. The M7 can be configured in 3 ways:

- Abrasive Blasting. Can blast either wet or dry.

- Power Wash surface cleaning

- Ultra High Pressure (UHP) coating removal.

-

RUBVDV400BlastOne's VertiDrive V400 Closed-Loop UHP Robot represents the pinnacle of surface preparation technology, engineered to revolutionize large-scale Ultra High Pressure (UHP) projects. This next-generation robotic system, exclusively developed by BlastOne, sets a new industry standard for efficiency, cleanliness, and safety in industrial surface treatment. RENT or PURCHASE this surface preparation work-horse! The next-generation V400 Ultra High Pressure VertiDrive. Bringing enhanced technology to closed-loop UHP projects.

- Faster. V400 robotic technology is up to 5X faster than manual work.

- Cleaner. The rust, coatings, and contaminants are removed and returned to the vacuum via the closed-circuit system.

- Safer. Remote control operation removes the operator from harms way.

- Capable. Boosted magnetic performance allows standard operation on carbon steel surfaces that are horizontal, vertical, and even upside-down!

- Environmentally friendly. Contaminants don't just fall to the surface or blow away in the wind. The V400 brings them back to the vacuum source for responsible disposal.

- Productive. Has an extra-wide 15.5" (400 mm) cleaning width

RUBVDV400BlastOne's VertiDrive V400 Closed-Loop UHP Robot represents the pinnacle of surface preparation technology, engineered to revolutionize large-scale Ultra High Pressure (UHP) projects. This next-generation robotic system, exclusively developed by BlastOne, sets a new industry standard for efficiency, cleanliness, and safety in industrial surface treatment. RENT or PURCHASE this surface preparation work-horse! The next-generation V400 Ultra High Pressure VertiDrive. Bringing enhanced technology to closed-loop UHP projects.- Faster. V400 robotic technology is up to 5X faster than manual work.

- Cleaner. The rust, coatings, and contaminants are removed and returned to the vacuum via the closed-circuit system.

- Safer. Remote control operation removes the operator from harms way.

- Capable. Boosted magnetic performance allows standard operation on carbon steel surfaces that are horizontal, vertical, and even upside-down!

- Environmentally friendly. Contaminants don't just fall to the surface or blow away in the wind. The V400 brings them back to the vacuum source for responsible disposal.

- Productive. Has an extra-wide 15.5" (400 mm) cleaning width

-

VCBRSMP46FREE Shipping 30 Day Money-Back Guarantee | Free Returns 90 Day Manufacturer Warranty

- Blasting rate up to 20 ft2 per hour. Due to this low production rate, this unit is intended for specialty applications, such as spot-work in dust-sensitive areas.

- Utilizes the TeraValve XL abrasive metering valve

- Compressed Air Requirement is only 185 cfm

- Has wheels and fork pockets for easy portability by hand, or by forklift.

- 100% compressed air powered - no electricity required

- Various workheads are available for flat surfaces, inside corners, outside corners, etc. - enquire for details.

- Genuine Products - Manufactured by Schmidt / Axxiom Manufacturing

VCBRSMP46FREE Shipping 30 Day Money-Back Guarantee | Free Returns 90 Day Manufacturer Warranty- Blasting rate up to 20 ft2 per hour. Due to this low production rate, this unit is intended for specialty applications, such as spot-work in dust-sensitive areas.

- Utilizes the TeraValve XL abrasive metering valve

- Compressed Air Requirement is only 185 cfm

- Has wheels and fork pockets for easy portability by hand, or by forklift.

- 100% compressed air powered - no electricity required

- Various workheads are available for flat surfaces, inside corners, outside corners, etc. - enquire for details.

- Genuine Products - Manufactured by Schmidt / Axxiom Manufacturing

-

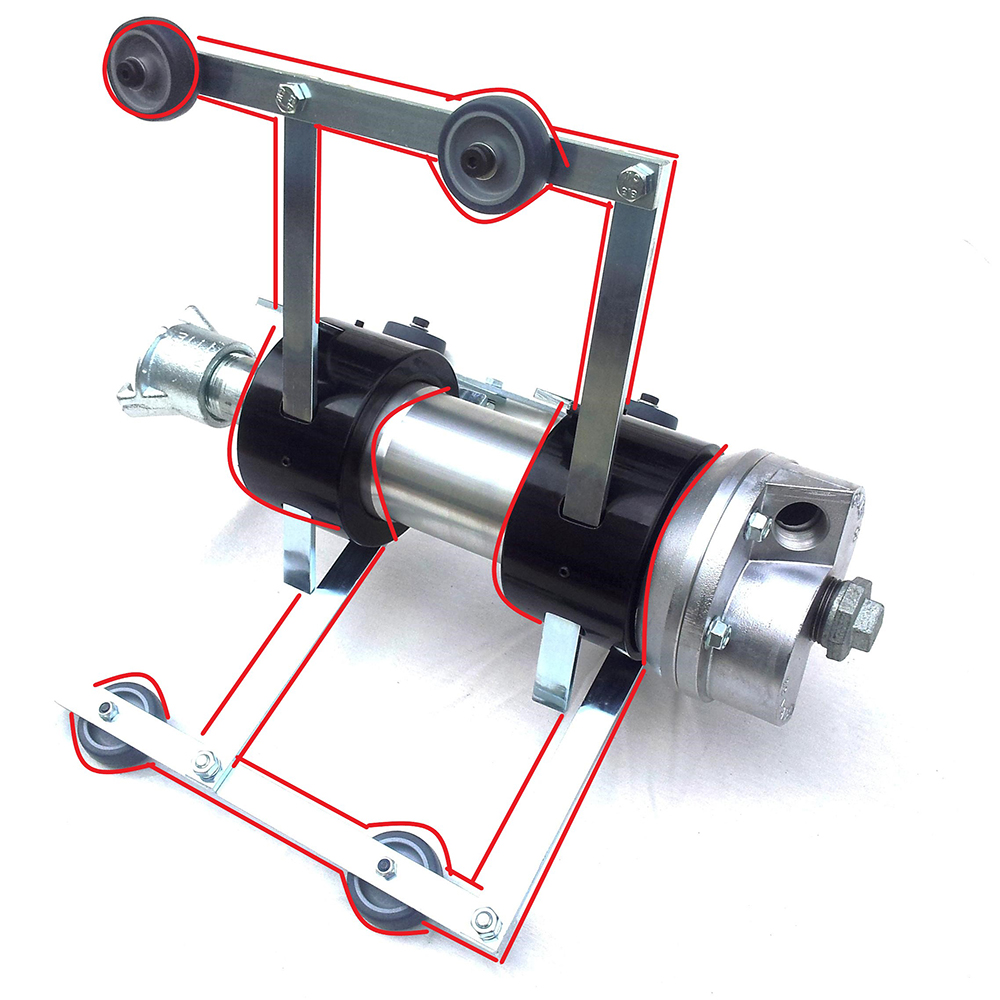

IPC1200

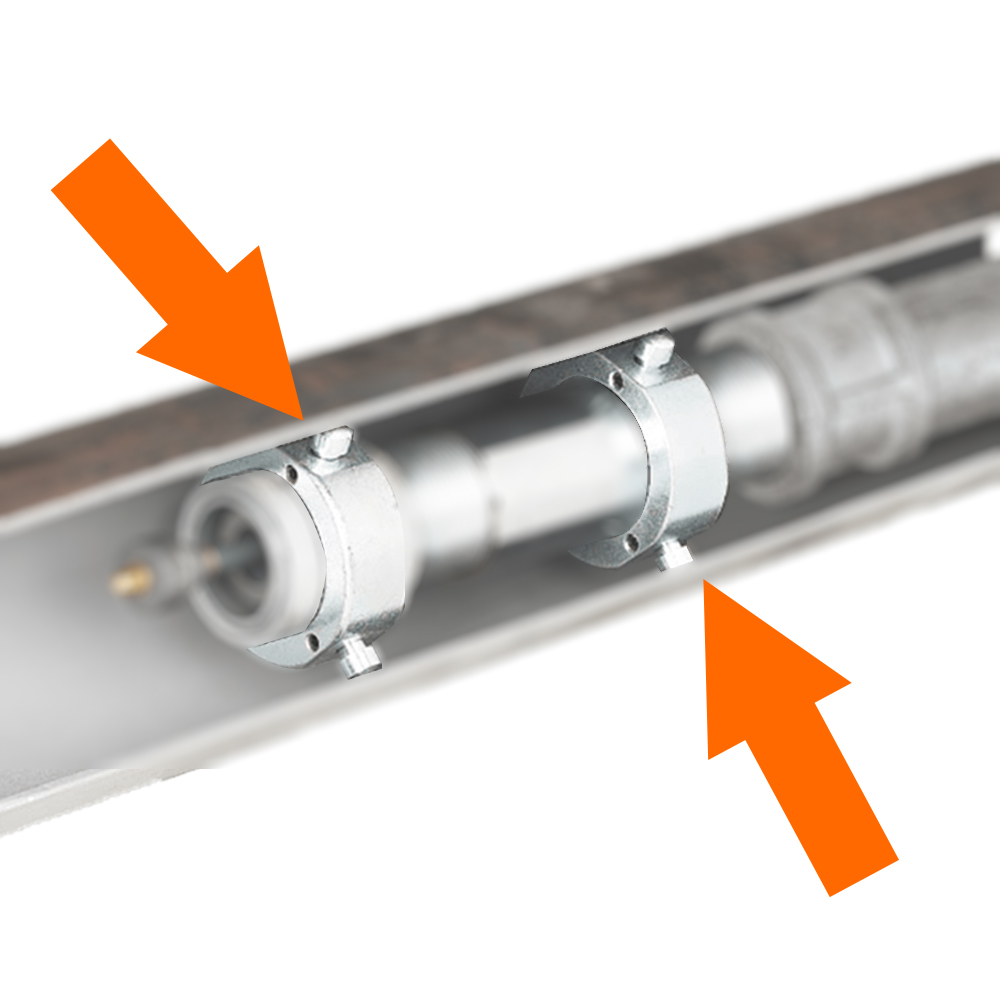

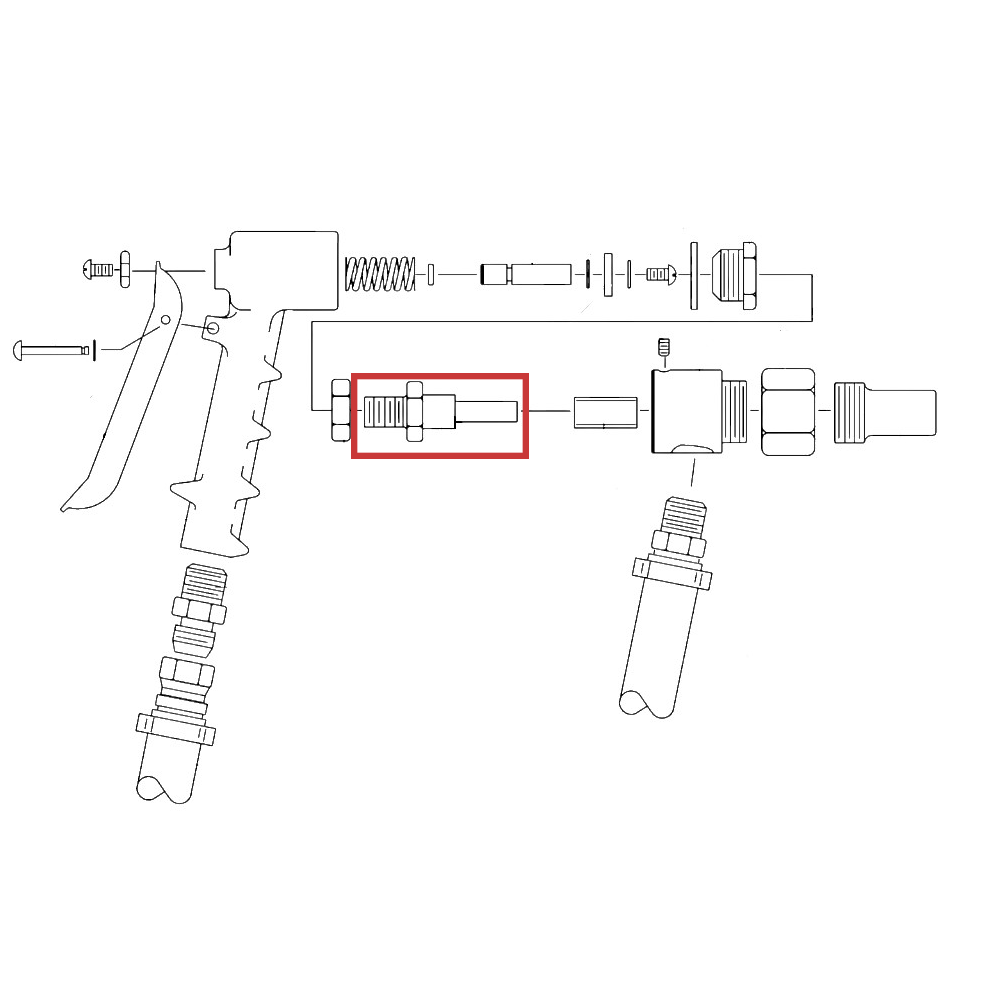

- Fits to IPC1000 as one assembly (outlined in red in image)

- Suitable for pipes between 10" and 35" in diameter

- Consists of 2 collars, 3 two-wheel roller bars and 4 sets of centering legs (6 legs per set)

IPC1200- Fits to IPC1000 as one assembly (outlined in red in image)

- Suitable for pipes between 10" and 35" in diameter

- Consists of 2 collars, 3 two-wheel roller bars and 4 sets of centering legs (6 legs per set)

-

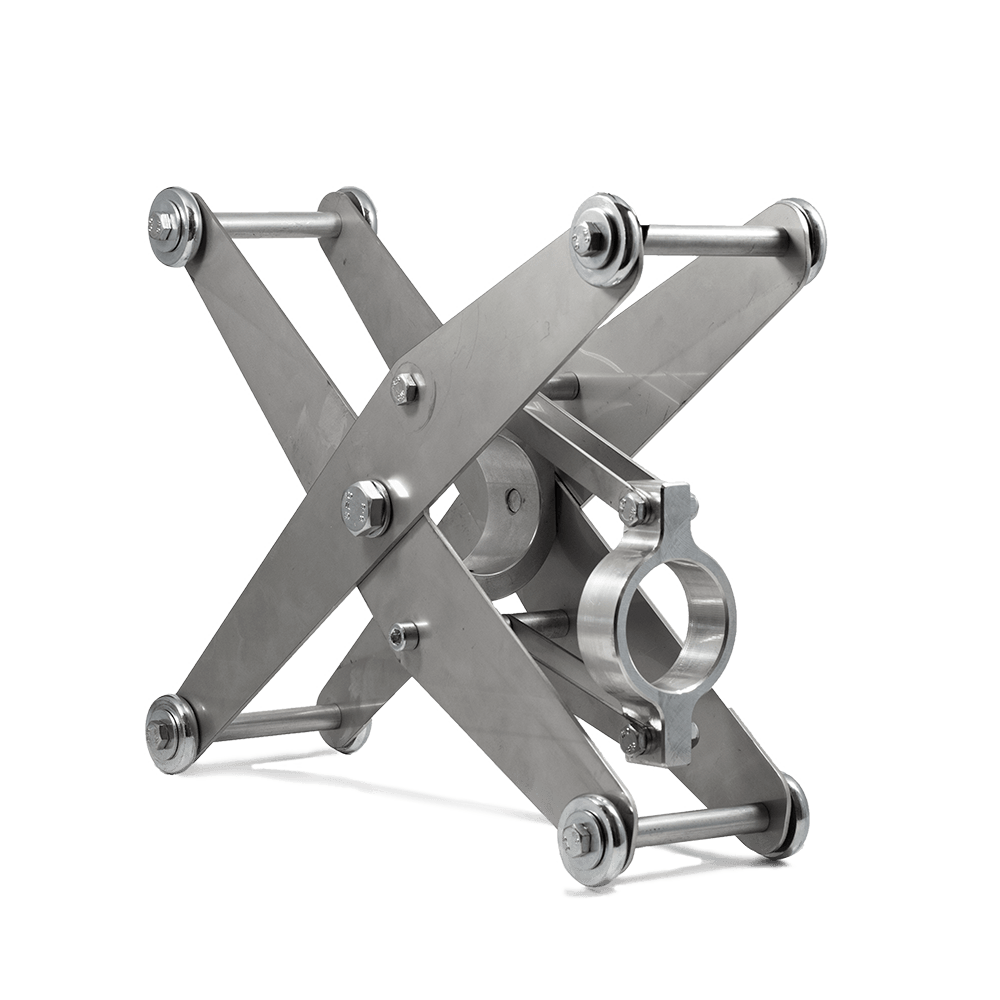

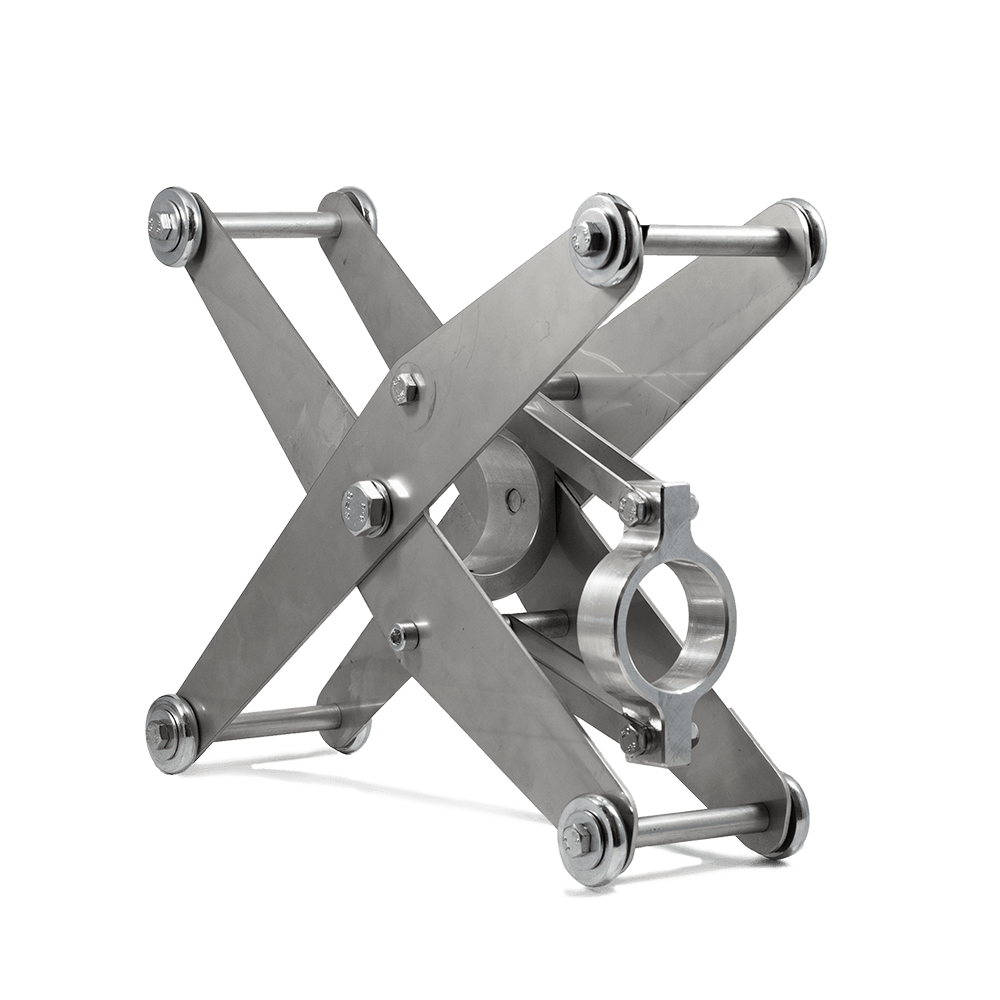

IPC4200

- Suits IPC4000 and IPC4500 ConeBlast Pipe Blasting System

- Ideal for blasting pipes between 5'' - 12'' internal diameter

- 'Scissor Type' Centering Carriage

- Sold Individually

IPC4200- Suits IPC4000 and IPC4500 ConeBlast Pipe Blasting System

- Ideal for blasting pipes between 5'' - 12'' internal diameter

- 'Scissor Type' Centering Carriage

- Sold Individually

-

HT3202404T

-

-

- FREE Shipping

- 30 Day Money-Back Guarantee | Free Returns

- 8" cutting width

- Easy to use, maintain and maneuver

- Precise screw type scaling head adjustment

- Angled dust port allows connection of industrial dust collector giving virtually dust free performance

- Supplied complete & ready to work with cutter head

- Updated version with improved electrics and start switch

-

HT3202404T-

-

- FREE Shipping

- 30 Day Money-Back Guarantee | Free Returns

- 8" cutting width

- Easy to use, maintain and maneuver

- Precise screw type scaling head adjustment

- Angled dust port allows connection of industrial dust collector giving virtually dust free performance

- Supplied complete & ready to work with cutter head

- Updated version with improved electrics and start switch

-

-

-

The Clemco SGT Air Jets are high-quality replacement components designed to optimize the performance of your SG-300 Suction Gun. Available in multiple sizes, these air jets ensure maximum efficiency by matching the available air supply to the blasting requirements. Key Features:

- These specially designed Clemco Suction Gun SG300 Air Jets are available in four orifice sizes:

- 1/16" orifice, MPN: 02659

- 1/8" orifice (standard), MPN: 02660

- 3/16" orifice, MPN: 02661

- 1/4" orifice, MPN: 02662

- Helps the SG-300 Suction Gun achieve optimal performance by matching air supply to application needs.

- Durable construction for long-lasting use in abrasive blasting environments.

- Genuine Clemco replacement part ensures compatibility and reliable performance.

- These specially designed Clemco Suction Gun SG300 Air Jets are available in four orifice sizes:

-

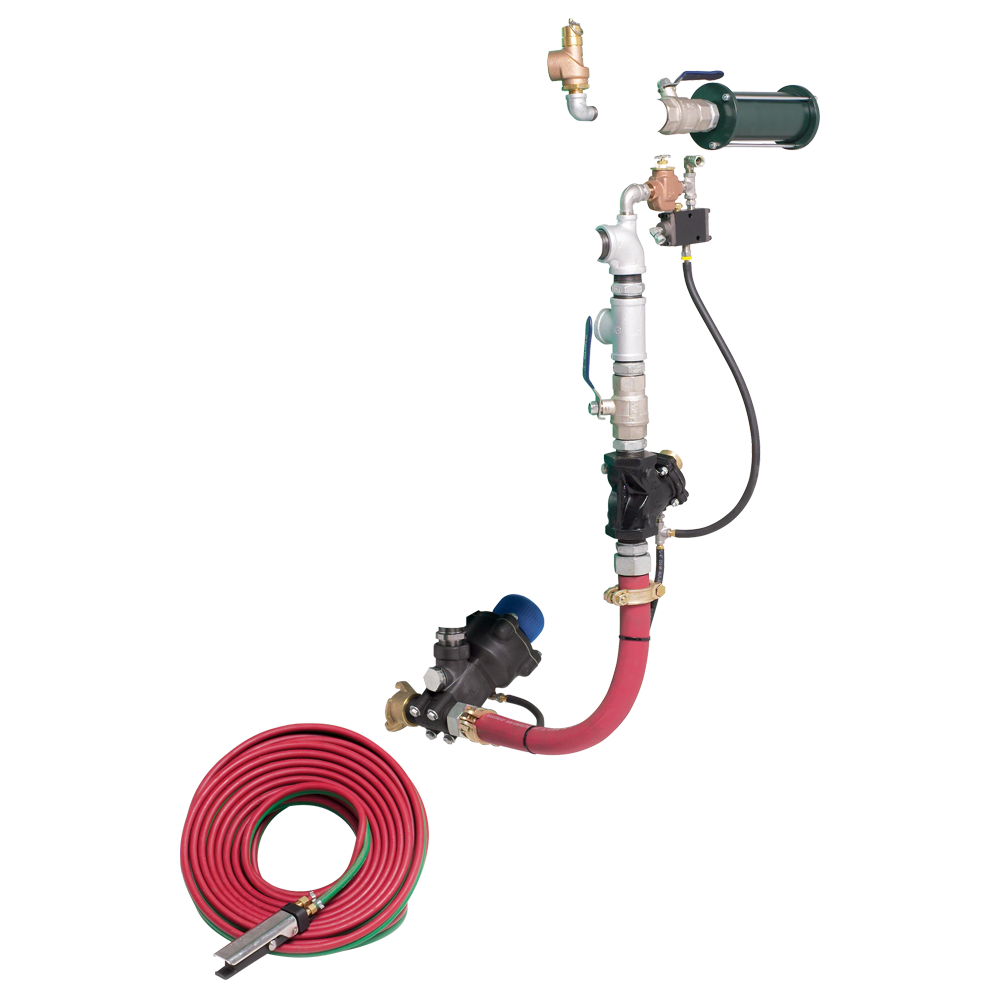

CAPSG02641Designed for abrasive blasting applications with limited air supply, the Suction Blaster is intended for small projects / touch-up work, etc. This complete setup (compressor and abrasive not included) can blast with as little as 12 cfm, using the included #5 nozzle and 1/8" air jet. The package includes the following:

- Light-duty, portable hopper with top screen

- SG-300 blast gun with #5 nozzle and 1/8" air jet

- 10' air hose, 1/2" ID

- 10' blast hose, 1/2" ID

- Package as shown MPN: 02641

CAPSG02641Designed for abrasive blasting applications with limited air supply, the Suction Blaster is intended for small projects / touch-up work, etc. This complete setup (compressor and abrasive not included) can blast with as little as 12 cfm, using the included #5 nozzle and 1/8" air jet. The package includes the following:- Light-duty, portable hopper with top screen

- SG-300 blast gun with #5 nozzle and 1/8" air jet

- 10' air hose, 1/2" ID

- 10' blast hose, 1/2" ID

- Package as shown MPN: 02641

Why Choose BlastOne’s Blast Equipment?

BlastOne’s blast equipment stands out for its reliability and innovation. Features like ergonomic designs, efficient media usage, and compatibility with various abrasives make our equipment a preferred choice. Our products are backed by expert support and comprehensive training resources, ensuring you get the most out of your investment.

Stay ahead in your projects with equipment that meets stringent industry standards and adapts to evolving needs. Trust BlastOne for solutions that enhance productivity and deliver consistent results.

My Account

My Account

Small Blast Pots

Small Blast Pots Contractor Blast Pots

Contractor Blast Pots Specialty Blast Pots

Specialty Blast Pots MistBlaster Wet / Dry Pots

MistBlaster Wet / Dry Pots Mega Bulk Blasters

Mega Bulk Blasters Robotic / Vertidrive Equipment

Robotic / Vertidrive Equipment Track Blasters

Track Blasters Internal Pipe (ID) Systems

Internal Pipe (ID) Systems Blast Machine Accessories

Blast Machine Accessories