Blast Nozzles

ABRASIVE MEDIA SANDBLASTING NOZZLES

BlastOne is a leading supplier of sandblast nozzles to industrial blast and paint companies worldwide. Our team is able to recommend the best type for your application whether you seek long lasting sini silicon nitride nozzles with a tough polyurethane jacket, tungsten carbide lasting 100-250 hours, standard silicon carbide or even alumina.

We also offer our blast nozzles in either contractor, medium, or fine threaded options. Whether you’re interested in trying a new type or simply replace an old favorite, give BlastOne a call and let us ship one out today.

Showing 1–15 of 45 results

-

The BlastOne Infinity Blast Nozzle is the latest proprietary advancement in blasting nozzle technology from the innovators behind the SnakeBite silenced nozzle. Engineered for durability and precision, this general-purpose nozzle delivers extended wear life and a consistent blast pattern across a wide range of industrial applications.

- BlastOne’s newest innovation in blasting nozzle design

- Approximately 6" overall length for versatile use. NOTE: For applications with sufficient space, hyper performance is available in our Infinity XL blast nozzle.

- The proprietary design of the silicon nitride liner minimizes internal turbulence

- Urethane outer jacket provides rugged durability

- Jam-resistant contractor threads ensure easy installation

- Available in orifice sizes: #6, #7, and #8

- Delivers consistent blast pattern and reduced abrasive consumption

NOTE: Infinity nozzles are not compatible with water-ring attachments.

-

The BlastOne Infinity XL Performance Blast Nozzle is possibly the fastest blasting nozzle available, boasting a 35% performance increase over standard blast nozzles. This nozzle, which was designed to be high-speed with extended-wear, was engineered by the developers of the iconic SnakeBite silenced nozzle. Developed with an advanced extended venturi and space-age liner, this proprietary innovation maximizes blasting velocity and efficiency in demanding industrial environments.

- Increases blasting performance by 35% over standard blast nozzles

- Latest proprietary design from BlastOne’s nozzle technology line

- 11–13" overall length depending on orifice size. NOTE - for applications not needing the Hyper nozzle performance of the Infinity XL, our 6" long standard Infinity nozzle is excellent and is ideal where access is limited.

- Proprietary silicon nitride liner for low turbulence and long life

- Durable urethane jacket withstands harsh job conditions

- Contractor-grade threads resist jamming during use

- Available in orifice sizes: #6, #7, and #8

- NOTE: Infinity nozzles are not compatible with water-ring attachments.

-

Get your new abrasive blasting pot set up right with this BlastOne Hose & Nozzle Bundle Package. Built for contractors, each package includes air and blast hoses, the latest Infinity nozzle technology, and all the essentials you need—all with the trusted BlastOne quality. Save money versus buying a la carte and pick the option that fits your job best.

- Bundle Group 1: Includes options with 50' blast hose & standard setup for shorter hose length and/or smaller compressor capacity

- Bundle Group 2: Includes options with 100' blast hose & extended setup for larger jobs and/or higher air flow

- Includes the latest BlastOne Infinity nozzle in your choice of orifice size

- Save time & money with these all-in-one contractor-ready kits

- BlastOne quality—built to perform in the field

-

Snakebite. The world's quietest blast nozzle!

BlastOne's SnakeBite XQ Silenced Blast Nozzle is engineered to be the world's quietest blast nozzle, prioritizing both operator safety and comfort. This innovative nozzle, exclusively designed by BlastOne, significantly reduces noise levels while enhancing performance, making it an essential tool for professionals in the blasting industry.- Up to 16dBA noise reduction

- Up to 45% less thrust compared to standard blast nozzles, greatly reducing operator fatigue and improving safety at heights

- Improved nozzle geometry

- New technology quick-connect nozzle silencer

- Durable and lightweight Silicon Nitride nozzle and silencer liner

- Slim ergonomic nozzle jacket

- Available with Contractor threads only, which are recommended. If Fine thread nozzle holders are a site requirement, use a Nozzle Thread Adaptor.

- 2 versions available

- Standard Pressure Nozzle effective between 90-110 psi

- Low Pressure (LPS) Nozzle effective between 70-90 psi

- FREE TRIAL AVAILABLE

- Click for Buying Guide

-

All the power. Half the size!

BlastOne's SnakeBite Flex Silenced Blast Nozzle is the ultimate solution for blasting in tight spaces without compromising power or performance. Exclusively engineered by BlastOne, this compact nozzle delivers all the benefits of the SnakeBite family, including noise reduction and reduced operator fatigue, while being small enough to navigate hard-to-reach areas with ease.- Up to 16dBA noise reduction

- Up to 45% less fatigue compared to standard blast nozzles

- Improved nozzle geometry

- New technology quick-connect nozzle silencer

- Durable and lightweight Silicon Nitride nozzle and silencer liner

- Slimline ergonomic nozzle jacket

- Standard contractor nozzle inlet thread

- 2 versions available

- Standard Pressure Nozzle effective between 90-110 psi

- Low Pressure (LPS) Nozzle effective between 70-90 psi

- FREE TRIAL AVAILABLE

Act quick! Limited supply.

-

BNSBXQ10-1BlastOne's SnakeBite Strike #10 Silenced Blast Nozzle is engineered to deliver the highest productivity in hand-held blasting, making it an essential tool for professionals tackling extensive surface preparation tasks. This innovative nozzle, exclusively developed by BlastOne, offers unparalleled performance with significantly reduced operator fatigue.

- WATCH VIDEO IN THE IMAGE SLIDER

- Highest productivity hand held blast nozzle available

- Over double the productivity of a #8 high performance blast nozzle with less operator fatigue

- Half the thrust of other #10 blast nozzles available - Feels like you're blasting with a #7 nozzle

- Up to 16dBA noise reduction - That's 75% quieter!

- Ideal for blasting acres of steel such as storage tanks, bridges and ship hulls

- Standard contractor nozzle inlet thread

- Delivers faster cleaning rates and increased profit by reducing project duration

- Requires 750cfm compressor

- FREE TRIAL AVAILABLE!

BNSBXQ10-1BlastOne's SnakeBite Strike #10 Silenced Blast Nozzle is engineered to deliver the highest productivity in hand-held blasting, making it an essential tool for professionals tackling extensive surface preparation tasks. This innovative nozzle, exclusively developed by BlastOne, offers unparalleled performance with significantly reduced operator fatigue.- WATCH VIDEO IN THE IMAGE SLIDER

- Highest productivity hand held blast nozzle available

- Over double the productivity of a #8 high performance blast nozzle with less operator fatigue

- Half the thrust of other #10 blast nozzles available - Feels like you're blasting with a #7 nozzle

- Up to 16dBA noise reduction - That's 75% quieter!

- Ideal for blasting acres of steel such as storage tanks, bridges and ship hulls

- Standard contractor nozzle inlet thread

- Delivers faster cleaning rates and increased profit by reducing project duration

- Requires 750cfm compressor

- FREE TRIAL AVAILABLE!

-

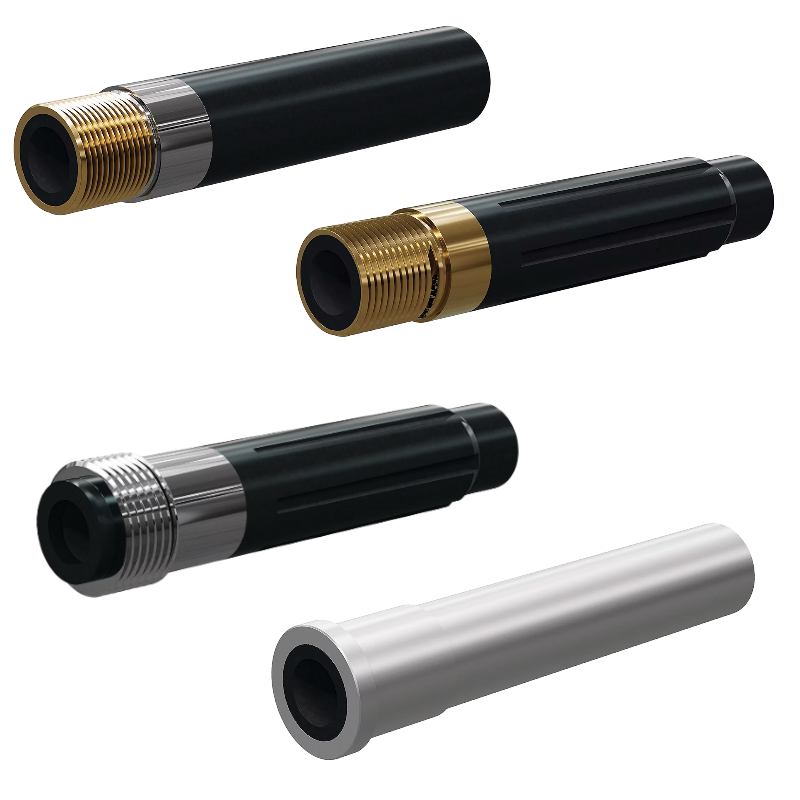

Designed with an extra-long venturi and concentrated blast pattern, the Hyper (aka XL or Saber) nozzle increases performance substantially. Additional details as follows: Click for Buying Guide

- Performance characteristics:

- Up to 30% faster coating removal and/or

- Allows greater stand-off distance (reduces need to bend over when blasting tank floors, allows greater reach, etc.)

- Thread types & Orifice Size options:

- Contractor 2" (50mm)

- Fine 1-¼" (32mm)

- Orifice size options: 5, 6, 7, 8, & 10

- Liner Options:

- SiALON silicon nitride, provides longer life and lighter weight than tungsten carbide.

- TC tungsten carbide, lower initial investment

- Jacket:

- Most are all aluminum with non-slip knurled finish, some have a poly jacket

- Design:

- 1-¼" throat entry, extended venturi, 12 inches long

- Performance characteristics:

-

The Ultra-Tuff Extended Life Silicon Nitride Blast Nozzle (SKU: P-BNULTRA) is built for industrial blasting, lasting twice as long as standard nozzles while being lightweight and highly efficient. Its Venturi design boosts productivity by up to 40%, and the durable silicon nitride liner with a shock-absorbent polyurethane jacket ensures exceptional performance. Click for Buying Guide Features:

- Venturi bore: 40% faster production than straight bore nozzles.

- Thread options: Contractor (2” / 50mm) and Fine (1-¼” / 32mm).

- Orifice sizes: #3–#8 to suit various tasks.

- Throat Entry:

- 1″ throat entry on #3 and #4 Contractor thread AND all Fine thread options

- 1-¼” throat entry on #5, 6, 7, and 8 Contractor threads

- Silicon nitride liner: Longer life, lighter than tungsten carbide.

- Polyurethane jacket: Protects against shocks and jams in metal holders.

- Lightweight: Reduces operator fatigue, half the weight of tungsten carbide.

-

BlastOne's SnakeBite XP Blast Nozzle is the high-performance alternative to the popular SnakeBite XQ silenced configuration. Designed for professionals seeking maximum blasting efficiency, the XP model utilizes a simple bump cap instead of a silencer, resulting in unmatched speed and performance without the noise and thrust reduction features of its counterpart.

-

Performance:

- The advanced modeling used when designing this Snakebite XP hyper nozzle has taken blasting performance to a whole new level. The refined internal geometry coupled with the non-silencing bump cap produces very fast cleaning speed indeed.

-

Liner:

- The new internal geometry when combined with the silicon nitride composition extends usable life greatly.

-

Jacket:

- Anodized aluminum with an ergonomic shape makes for a very comfortable grip.

-

Sizes:

- Available in the following orifice sizes: 6, 7, 8, & 10

- Overall length varies from 10" to 13", depending on orifice size.

-

Thread type:

- Available in standard 2" Contractor thread only. (See You May Also Like nozzle thread adapters below if you want to use with fine thread nozzle holders.)

Note: Inquire for details about our free trial offer.

-

Performance:

-

The SnakeBite Blast Nozzle Silencers are direct-fit replacements for BlastOne’s SnakeBite nozzle series, engineered to cut noise and fatigue while maintaining high-performance blasting. Designed for noise-sensitive environments, these silencers boost operator comfort and jobsite compliance.

- Up to 16 dB noise reduction for safer operation

- Two models: Standard (90–110 PSI) and Low Pressure (70–90 PSI)

- Fits all SnakeBite nozzle models

- Up to 45% less operator fatigue during blasting

- Easy install—no special tools needed

-

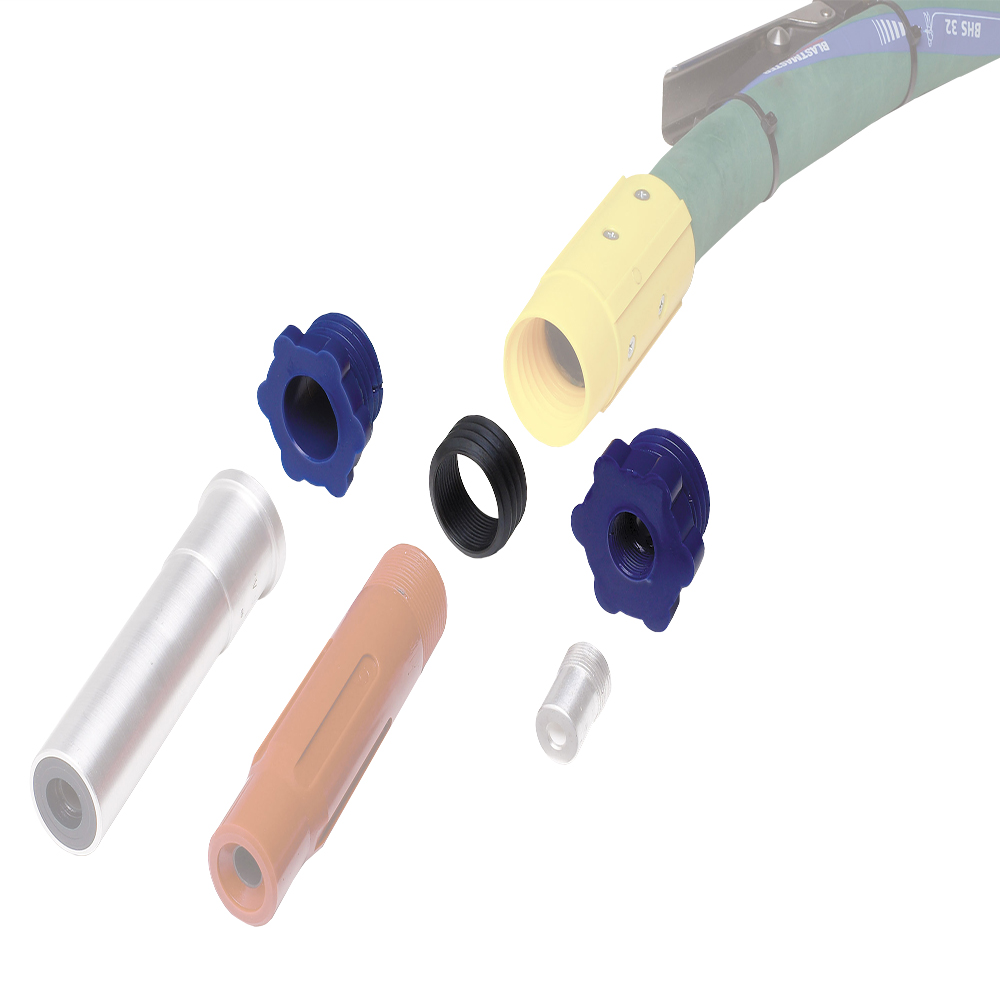

Designed with a 60% larger blast pattern, the Raptor (aka Bazooka) nozzle makes short work of your large commercial blast / sweep blast / brush blast projects. Additional details as follows: Click for Buying Guide

- Thread types:

- Contractor (2") aluminum threads

- Fine (1-¼") brass threads

- Liner Options:

- Silicon nitride, offers lighter weight and generally longer life than tungsten carbide.

- Tungsten carbide

- Jacket:

- Urethane, for improved resistance to damage

- Design:

- 1-¼" throat entry, extended venturi

Note: As the Bazooka nozzles have metal threads, they work best with nylon nozzle holders and HFG32P (NW-32) nozzle washers.

- Thread types:

-

INBNATMaintain optimal blasting efficiency with our Abrasive Blasting Nozzle Wear Gauge Set, designed for quick and accurate assessment of nozzle wear in sizes #6, #7, #8, and #10. Featuring an extended design, this tool allows for measurements without removing the nozzle from its holder and eliminates the need for additional instruments like pencils. Regular use helps detect wear as small as 1/32", ensuring timely nozzle replacements to maintain peak performance.

- Measures nozzle sizes: #6, #7, #8, and #10

- Detects wear starting at 1/32"

- Extended length enables in-place measurements without nozzle removal. Simply drop in the applicable gauge into the end of the nozzle and if it goes through, it's time to replace!

- No additional tools required for operation

- Enhances blasting efficiency by identifying worn nozzles promptly

- Durable construction for long-term use

INBNATMaintain optimal blasting efficiency with our Abrasive Blasting Nozzle Wear Gauge Set, designed for quick and accurate assessment of nozzle wear in sizes #6, #7, #8, and #10. Featuring an extended design, this tool allows for measurements without removing the nozzle from its holder and eliminates the need for additional instruments like pencils. Regular use helps detect wear as small as 1/32", ensuring timely nozzle replacements to maintain peak performance.- Measures nozzle sizes: #6, #7, #8, and #10

- Detects wear starting at 1/32"

- Extended length enables in-place measurements without nozzle removal. Simply drop in the applicable gauge into the end of the nozzle and if it goes through, it's time to replace!

- No additional tools required for operation

- Enhances blasting efficiency by identifying worn nozzles promptly

- Durable construction for long-term use

-

- Curved "Banana" Blast Nozzle

- Made from Boron Carbide which is the longest lasting material used for blast nozzles

- Size listed is a #6, which is 3/8" internal diameter

- Has a Medium 3/4" Thread - Requires a special nozzle holder adapter

- Search for “nozzle thread adaptors” to select an adaptor to use with your existing nozzle holder, or contact BlastOne if you want a medium thread nozzle holder.

- Sold Individually

My Account

My Account

Silenced / Quiet Nozzles

Silenced / Quiet Nozzles Angled Blast Nozzles

Angled Blast Nozzles General Purpose Nozzles

General Purpose Nozzles Internal Pipe (ID) Nozzles

Internal Pipe (ID) Nozzles Short / Compact Nozzles

Short / Compact Nozzles Nozzle Tools Parts & Adapters

Nozzle Tools Parts & Adapters Wet-Blast, Specialty & Other Nozzles

Wet-Blast, Specialty & Other Nozzles